Social and Relationship Capital

Our unwavering focus on fostering long-term connections with customers, suppliers, and communities lies at the heart of our business sustainability and forms an integral part of our core strategy.

SDGs impacted

0*

Customer satisfaction index

0 mn+*

Lives impacted

through

CSR activities

0*

Supply chain partners assessed

*(Tata Steel Limited only)

Material issues addressed

- Water Consumption and Effluent Discharge / Water Resource Management

- Community Support and CSR / Building thriving Communities

- Stakeholder Engagement

- Business Ethics, Integrity, and Transparency

- Risk Management

- Supply Chain Sustainability

Strategic linkages

Customers

SO1

SO3

SE

Suppliers

SO2

SO4

SE

Communities

SO4

SE

Nurturing relationships for sustainable growth

Growing with our customers

FY2022-23 turned out to be a year

where we have focused on elevating

our relationship with customers to the

next level in line with theme for the

year 'Vision Next – strive to own the

future'. Despite the global headwinds,

we remained steadfast in the belief

that customer focus alone can result in

superior performance. Digital initiatives

and platforms served as a major

backbone in achieving a new customer

base, enabling more customer

centric engagements, and easing the

order flow.

Customer Meet

Working with Business to Business (B2B) customers

We continued our efforts to enhance our relationship with automotive OEMs and their large value chain partners. Considering the changing business requirements and to serve the customers better, Tata Steel focussed on fast-growing Light Commercial Vehicle segment, technical services offerings such as Vehicle Teardown and Benchmarking Services, Early Vendor Involvements on upcoming models amongst others and broadening supply chain capabilities through new processing partners. Further, our flagship initiative for weight and cost reduction - VAVE (Value Analysis & Value Engineering) and supply chain visibility through COMPASS platform have enhanced value driven engagements with customers.

In servicing non-automotive segment (Industrial Products, Projects & Exports), we have entered into a MOU with a key Oil & Gas player for the development of hot rolled steel for green hydrogen pipeline. Customer Service Teams with key customer accounts continued to play a pivotal role. VAVE initiatives for Lifting & Excavation segment also helped in customer value creation. As part of the digital initiatives, we have increased onboarding of customers on COMPASS platform covering ~ 67% of sales, while continuing to add new customised features. We have also collaborated with various academia and industry bodies to increase usage of flat steel products in construction segment in India. Knowledge summit “Wired2Win” for Wire Rod customers was relaunched for enhancing customer connect through networking and cross market knowledge sharing. In partnership with our overseas customers, first ever Electronic Bill of Lading for exports into Turkey was pioneered.

Tata Steel offers branded products uniquely positioned to meet the application needs of B2ECA (Business to Emerging Corporate Accounts or MSME) customers and we reach our MSME customers through a panIndia distribution network. Multiple engagement initiatives in a phygital manner have been undertaken on the ECAfez Qualithon platform. Some key offline initiatives include, customised microsegment meets like ‘Ducticon’ (ducting & heating, ventilation, and air conditioning customers) & ‘Panorama’ (panel customers). Knowledge exchange & capability building initiative, ‘insIITe’, was held in collaboration with IIT Mumbai. Online initiatives like Skilling India, Tech Talk and Safety First have helped improve the knowledge base of customers by connecting over 500 MSME customers online.

We have been working on

customised solutions for our long

products customers. In FY2022-23 four

‘Building Bonds’ and eight ‘Converse

to Construct’ events were organised

to facilitate the interactions of

channel partners, end-customers and influencers with the senior leadership

of Tata Steel. Similarly, four ‘Igni8:

The Spark’, monthly webinar sessions

were conducted, success stories of

channel partners and shared segment

specific knowledge in collaboration

with academia and Industry experts

were showcased.

Working with retail (B2C) customers

Tata Steel brand offerings (Tata Tiscon, Tata Saktee, Tata Kosh) to the retail consumers have attained respect and recognition by virtue of their quality. Tata Tiscon, under the Golden Home Consumer initiative, connected with 26,000+ consumers. 500+ Ask Experts camps were conducted across India to provide guidance in home construction to individuals. “Stories of Joy” – a consumer testimonial series was curated with 30+ stories released in FY2022-23.

Our Flagship galvanised brands, Tata Shaktee (Galvanised Corrugated Sheets) and Tata Kosh (Branded Galvanised Product) organised the 3rd edition of Nexplore, the Annual Dealer Meet where top 250 dealers and fabricators were engaged. As part of our ‘Farmers Day’ celebrations, 22,000 farmers were connected directly through Kissan Diwas Meets, reaching out to 74 million people. 51,000 prospective consumers were directly reached out to daily by the “Gaon Gaon Shaktee ki Chaon” campaign. In addition to this, Tata Steel connected directly with nearly 15,000 fabricators, 8,000 dealers, 600 sub-dealers and 1 lakh consumers respectively, and additionally reached out to 84 lakh people through the social media platforms.

Our two solutions offerings – Tata Pravesh (Steel doors and windows) and NEST-IN (smart steel based modular construction solution) have consolidated their position as the market leader in a very competitive market. During the year under review, Tata Pravesh offered services through Authorised Service Centre – SmartCare, doubling our presence to 14 in FY2022-23. Additionally, Tata Pravesh expanded its Privileged Dealer network to 470 outlets.

The Nest-In brand has implemented the Salesforce Customer Relationship Management platform for end-to-end monitoring & control and a 360-degree customer view. A QR-code authentication for assurance of genuine products and augmented reality for select projects was introduced. The online lead generation model and new leads resulted in 60% increase in new customers. Nest-In has also upgraded to delivering luxurious and premium Nestudio.

Tata Pravesh - Steel Door & Windows

Nest-In – A steel-based modular construction solutions brand by Tata Steel

Collaborating for greener products

Tata Steel’s subsidiaries in the UK and Sweden are collaborating actively with CompETe partners (a collaboration to create a high-performance compact electric drive unit) for automotive customers. We are working on both ultra-thin non-grain-oriented electrical steel and 2D and 3D models for assessing the high-speed motor rotors’ structural integrity.

Tata Steel is also working on unique technologies such as Hardt Hyperloop, a high-speed, sustainable transportation system for people and goods in the Netherlands.

Transforming to become a leading producer of clean, green and circular steel

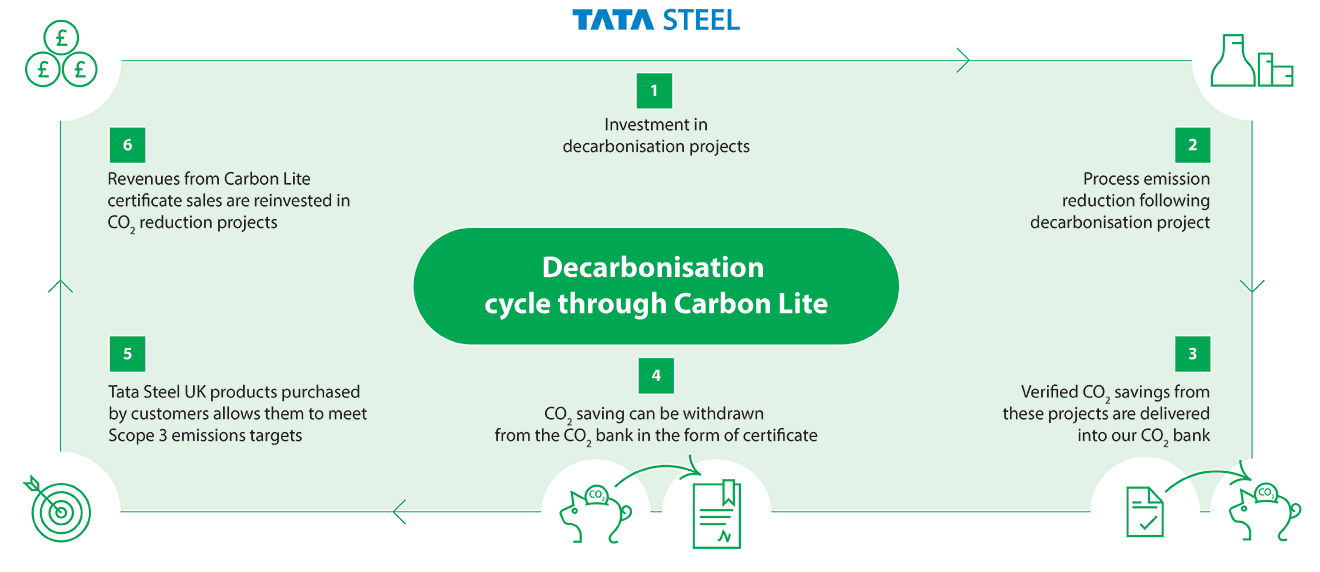

Tata Steel Nederland has started offering lower CO2 steel under the Zeremis® Carbon Lite brand since July 2022. We have constituted new agreements with Wuppermann, BILSTEIN, EMW Stahl Service and Arania to supply them with Zeremis® Carbon Lite steel with an allocated carbon footprint reduction of up to 90%. This will enable customers to make greener end products such as kitchens, robotic storage systems and passenger cars. We aim to offer large quantities of high-quality green steel by 2030 and additional Zeremis green steel products will follow in the near future. Tata Steel also offers Carbon Lite solution from its UK operations under the brand name Optemis™ Carbon Lite.

Tata Steel is also offering the opportunity to secure green steel from the upcoming hydrogen-based steelmaking route in the Netherlands and has signed a MoU with Ford within the year.

CO2 Project Bank and Insetting

Hyperloop – A high-speed, sustainable transportation system

Managing relationship with suppliers

Supplier management at Tata Steel focusses on performance enhancement of vendor partners to meet organisation's growing and varying needs, achieved through various cross-functional initiatives, as below:

![]()

Supplier Relationship

Management programme

The program aims to enhance

Tata Steel’s relationship with its

strategic vendors for promoting

innovation. In FY2022-23, Tata

Steel collaborated with 6 strategic

vendor partners to conduct

‘Technology Day’ sessions

focused on cutting-edge

technologies and processes

related to quality, delivery,

productivity, safety, digitalisation

and sustainability. It also focuses

on technology transfer and

establishing OEM workshops to

promote local manufacturing

through ‘Make in India’ initiative

(e.g. Manufacture Mag C bricks

& Tap hole sleeves and refurbish

critical import spares).

![]()

Senior Leadership Connect with strategic and key suppliers

Tata Steel has a structured leadership connect programme (‘CEO to CEO Connect’) to help strengthen its relationship and gain insights into the suppliers’ future growth plans and key focus areas. Through these interactions, strategic and long-term collaborative ideas are discussed which are subsequently implemented and rolled out. In FY2022-23, Tata Steel conducted such interactions with 11 strategic partners across all geographies.

Supplier Meet

![]()

Indeginisation &

localisation

In FY2022-23, indigenisation and localisation in the supply chain has continued to be a focus area for Tata Steel with indigenisation of I724 crore across raw materials, bulk items and maintenance, repair and operations spares using Agile Way of Working methodology. We have also leveraged our relationships with vendor partners to facilitate technology transfer, assist in setting up manufacturing facilities closer to our production centres and collaborate closely with local and Micro, Small and Medium Enterprise vendor partners, to establish manufacturing, refurbishment, or service centres. The key indigenisation initiatives which have been taken up in FY2022-23 are the Refurbishment of Crop shear & Down Coiler wrapper roll, Indigenous Sourcing of Impact crusher for flux, increased percentage of indigenisation of thermal coal and increased local sourcing for critical refractories and rolls.

![]()

Focused engagement with raw material suppliers

Developing partnerships through long-term projects in the imported coal value chain is critical for reducing the overall cost of production. Understanding of strategic plans of key suppliers and creating mutually beneficial products have helped maximise the coal supply with higher Value-inUse. Due to the Russia-Ukraine war, Tata Steel has stopped procuring coal from Russian suppliers and started sourcing replacement coal from both incumbent suppliers and new suppliers in North America, Australia, and Indonesia. This has facilitated supply chain security and inventory optimisation, leading to the efficient management of complex multi-site operations. We have engaged in specific collaborations with our raw material suppliers, leading to the development and trialling of new products as part of our product/ source diversification initiatives, signing of long-term agreement for domestic supply of thermal coal and development of steelmaking sludge based pellets by utilising hazardous waste. We have also signed Memorandum of Understanding with strategic suppliers for decarbonisation projects.

![]()

Vendor Development & Vendor Capability Advancement Programme (VCAP)

Tata Steel’s Vendor Development Programme and VCAP aim to support suppliers to foster a culture of continuous improvement, resulting in a competitive vendor base. During FY2022-23, we initiated 20 vendor development programmes across various locations. We have implemented projects to improve the ease of doing business, digitalisation projects such as setting up agile payment mechanisms at all locations and Vehicle Tracking system at Meramandali. We worked closely with our vendor partners to improve their productivity, safety, delivery, and quality performance through a structured approach, leading to their capability enhancement,

value creation and operational

improvements.

In FY2022-23, we

organised multiple VCAP sessions

and trained a total of 251 vendors

partners, impacting 5,000+

contracted workforce, on problem

solving, sustainability, operating

practices and safety best practices.

To support local communities

and encourage the inclusion of

marginalised sections of society,

we helped develop entrepreneurial

capabilities by creating positive

differentiation through our

Affirmative Action Programme. In

FY2022-23, the business volume

of such vendors has grown to

approximately `112 crore, 62%

increase over FY2022-23.

Improving delivery performance

Green Warehousing

![]()

Green warehousing

To minimise the environmental impact of our warehousing operations, we have installed a 3.2 MW solar plant at our Jamshedpur Central Warehouse. Additionally, we have replaced 10 dieseloperated trucks (used for last-mile delivery to operating units) and 2 diesel-operated forklifts in the warehouse with electric-powered ones in FY2022-23. In FY2023-24 we plan to convert another 10 dieseloperated trucks to greener fuels. As a result of our green warehousing initiatives, we have successfully reduced our environmental footprint by approximately 3,000 MtCO2 e. Tata Steel Halmstad and Naantali Service Centres in Sweden and Finland respectively are already fully Scope 1 and Scope 2 carbon neutral operations.

![]()

Surface transportation

Tata Steel has deployed 69 CNG/LNG/ Electric Vehicles (EV) based vehicles in short lead road circuit to reduce its CO2 footprint. This is being ramped up to almost double in FY2023-24. Also, in road transportation, we are exploring benchmark practices to enable real time CO2 measurement which will help us in reducing Scope 3 emission. In addition, we strive to improve operational efficiency in our supply chain operations (e.g. travel distance and idle weight optimsation) to further reduce the carbon footprint.

Deploying EVs for steel transportation

![]()

Material circularity

In our commitment towards material circularity, we have joined hands with our suppliers and implemented various initiatives to refurbish our capital equipment, increasing their lifespan and preventing unnecessary waste. In a first-of-its-kind initiative in India, we have successfully recycled 12,000 tonnes of used refractories. Through the refurbishment of critical imported spares in India, we have been able to reduce 200 MtCO2 e in FY2022-23 with a plan to further reduce CO2 emissions by 25% in FY2023-24.

![]()

Supply chain sustainability

Tata Steel is among select few companies to measure end-to-end Scope 3 emissions for all modes of transportation. Several initiatives are being taken across shipping, logistics and with vendor partners to reduce Scope 3 emission for a future-ready sustainable supply chain.

Leveraging inland waterways for steel transportation

![]()

Shipping

Tata Steel is the first and only steel producing signatory to the Sea Cargo Charter to measure and reduce environmental impacts of global seaborne trade. We have re-baselined and validated our CO2 footprint measurements as per the latest International Maritime Organisation guidelines and partnered with IHS Markit, for appropriate reporting. In ocean trade, we have limited the deployment of vessels having higher CO2 emissions and moved to energy efficient vessels. Tata Steel deployed 10 vessels powered by Alternate fuels (Biofuel), 7 for carrying raw materials from Singapore to the East Coast of India and 3 for movement of finished goods in Europe. We plan to increase it to 50+ biofuel/LNG based shipment in FY2023-24 across India and Europe. Cargo movement via coastal and river waterways is being ramped up to shift movement to greener mode of transportation. Recently, Tata Steel completed its first multimodal shipment of 960 MT of TMT bars from Haldia to Agartala. The barge traversed through Indo-Bangladesh protocol route and discharged the material at Ashuganj port in Bangladesh.

![]()

Responsible Supply Chain Policy (RSCP)

Our RSCP aims to sensitise the supply chain partners on the need for adhering to the four ESG principles of responsible supply chain i.e. Fair Business Practices (G), Health & Safety (S), Human Rights (S) and Environmental Management (E). We had identified 465+ critical partners across all categories of Procurement in India. For FY2022-23, we have assessed 211 critical suppliers under RSCP. The vendor development team has taken up joint improvement projects on the opportunities of improvements identified during the assessment, which led to an improvement in the sustainability performance score of 81 vendor partners. Tata Steel has onboarded all 40 Steel Processing Centres (SPCs) in the journey of RSCP after a detailed awareness session, who have been assessed and initiatives are being deployed against the same. Tata Steel has codified the rules for employment at SPCs for fair and unbiased selection. Rainwater harvesting system has been deployed at most of the SPCs and stockyards.

In FY2022-23, 4 SPCs (processing 1 MnTPA, ~55% volume) have moved to Furnace oil and 4 SPCs (processing 0.6 MnTPA, ~32% volume) to Low Sulphur Heavy stock /CNG based operations. Further, the SPCs currently on Coal / Furnace oil will also be taking a transition to Low Sulphur Heavy Stock/CNG based operations thus ensuring the entire 1.8 MnTPA is processed through alternate fuels. Solar panel coverage is being enhanced across the SPCs and stockyards.

Tata Steel Nederland, as a member of the International Responsible Business Conduct agreement known as the “Metaalconvenant”, is implementing the Organisation for Economic Cooperation and Development (OECD) due diligence guidelines and addressing the ESG risks in supply chain for purchased raw materials and important semifabricated products such as alloys and metals. In FY2022-23, we have formed a community of practice for sharing and learning between the relevant categories.

Way forward

We will continue working with our suppliers to improve their sustainability performance, reduce our supply chain risks and increase visibility in our upstream supply chain. We will drive further innovations in our supply chain in the areas of new and emerging technologies, digitisation, and advanced safety practices.

Nurturing sustainable communities

Tata Steel’s overarching vision to be the global steel industry benchmark for value creation and corporate citizenship is underpinned by a resolve to “work with tribal and excluded communities”. Tata Steel’s Corporate Social Responsibility (CSR) initiatives aim to create deep-rooted social capital through Tata Steel Foundation which has a diverse 1,000+ strong force of professionals who together with communities implement various development programmes:

The Maternal & Newborn

Survival Initiative (MANSI+) is

a decade long lifecycle health

programme.

The Maternal & Newborn

Survival Initiative (MANSI+) is

a decade long lifecycle health

programme.

Promoting Tribal Identity

continues for 9th season in the

Samvaad Ecosystem through work

on tribal culture. Johar Haat (a space

dedicated to bring the best of art,

craft, cuisine and talent from tribes

across India) and Rhythms of the

Earth (a platform for preserving and

promoting tribal music) launched.

Promoting Tribal Identity

continues for 9th season in the

Samvaad Ecosystem through work

on tribal culture. Johar Haat (a space

dedicated to bring the best of art,

craft, cuisine and talent from tribes

across India) and Rhythms of the

Earth (a platform for preserving and

promoting tribal music) launched.

Foundational Learning and

Numeracy model was rolled out

to more than two lakh children to

address COVID induced deficits.

Children from Masti Ki Pathshalas

are connected to internships to

improve overall personality and

confidence.

Foundational Learning and

Numeracy model was rolled out

to more than two lakh children to

address COVID induced deficits.

Children from Masti Ki Pathshalas

are connected to internships to

improve overall personality and

confidence.

Communities are supported

to earn their livelihoods through

agricultural and allied activities, as

well as through basic infrastructure,

community-based water

ecosystems and household level

nutritional gardens.

Communities are supported

to earn their livelihoods through

agricultural and allied activities, as

well as through basic infrastructure,

community-based water

ecosystems and household level

nutritional gardens.

Development Corridor

programme has enabled

preparation of Village Development

Plans and ensured that marginalised

citizens receive benefits from

linkages to Government schemes.

Development Corridor

programme has enabled

preparation of Village Development

Plans and ensured that marginalised

citizens receive benefits from

linkages to Government schemes.

Through SABAL, Persons with

Disabilities (PwDs) are supported

in capability building, entitlements

linkage and platform for expression.

Through SABAL, Persons with

Disabilities (PwDs) are supported

in capability building, entitlements

linkage and platform for expression.

Efforts are also taken for

building women leadership

within communities, nurturing

young sports talent through

grassroots training, providing

state/national/international

platforms and connecting them to

excellence centres.

Efforts are also taken for

building women leadership

within communities, nurturing

young sports talent through

grassroots training, providing

state/national/international

platforms and connecting them to

excellence centres.

Promoting livelihoods through agriculture

0 +

Strong force of

professionals

implementing various

development programmes

Tata Steel Chess Tournament

Globally, in Europe, Tata Steel UK and Nederlands are also working towards contributing to the local community’s social and economic well-being. The community partnerships are built on three main aspects i.e. environment, health & well-being, and education & learning. Some of the initiatives include community outreach programmes to promote sports like the Richard Burton 10k running event, and Kids of Steel mini-triathlons. The 85th edition of the Tata Steel Chess Tournament was organised in Netherlands in January 2023. We also organise events like Girls’ Day to introduce girls to technology and conducts site visits at Tata Steel in IJmuiden.

Development programmes undertaken in FY2022-23 and their impact

Signature programmes

The goal is to actualise national change models which address core development gaps in India. Over 1.78 million lives have been impacted through our Signature programmes in FY2022-23.

Promoting maternal and new-born health

For survival of women and children before, during, and after childbirth

Impact

- 7.87 lakh+ women and children reached through MANSI+

- Sexual and reproductive health knowledge enabled through RISHTA to 22,300+ adolescents

- Institutional delivery enabled for 86% of high-risk pregnancies identified

- 58% of under-5 children with severe acute malnutrition identified and treated

SDG linkage

Promoting education

Through a revitalised public education system

Impact

- Over 7.5 lakh children’s lives impacted through Education Signature Programme

- 30,516 children reached through learning programmes

- 2,46,867 children reached through Foundational Literacy and Numeracy

- 15,425 children brought back to school

SDG linkage

Promoting tribal identity

Through SAMVAAD Ecosystem which mainstreams the tribal culture.

Impact

- Samvaad ecosystem reached 1.39 lakh+ people

- 2,702 participants from 158 tribes across 24 states and UTs

- 33,560 tribal language learners across 572 centres of 130 blocks

- 26 publications in tribal languages

- 210 tribal healers reached, 227 healing practices documented, 5 herbal gardens created

- 43 lakh+ income generated by 169 tribal artisans

SDG linkage

Encouraging community-led development

In the vibrant Jamshedpur Kalinganagar corridor

Impact

- 56 Panchayats organising regular Gram Sabha meets

- 73 social schemes and govt. initiatives leveraged to 12,000+ individuals

- 144 Village Development Plans developed by panchayats

- 50% functional panchayats with key standing committees

- 39 Corridor Fellows engaged across 71 panchayats

SDG linkage

Proximate Community Development (PCD) Programmes

Build regional change models which enable lasting betterment in the well-being of communities, prioritising those who are excluded and proximate. Over 1.10 million lives have been impacted in FY2022-23.

Promoting livelihoods through agriculture and agri-allied based activities

Ensuring increase in aggregate real annual income for marginalised households

Impact

- 63,698 households with improved agricultural practices with average increase in income of ₹1,07,860

- 6,145 farmers engaged across 373 farmer institutions

- 9,067 farmers leveraged with government schemes

- 1,740 acres under irrigation coverage benefitting 3,417 households

SDG linkage

Promoting livelihoods through youth skill development

For a sustainable career path with stable income enhancement

Impact

- 2,759 youth gainfully engaged post completion of long and short-term courses

- 6,300+ youth from proximate geographies connected with Model Career Centre for capacity building

- 72 youth trained in entrepreneurial capabilities

SDG linkage

Augmenting public healthcare capacity

Ensuring public healthcare capacity meets national standards

Impact

- MoUs signed with authorities of 5 districts in Jharkhand (Gumla, Simdega, West Singhbhum, East Singhbhum and Seraikela Kharsawan) for upgradation of district hospitals

SDG linkage

Empowering rural women

With a platform that provides access to economic resources

Impact

- `36,000 additional income enabled annually for 1,182 women, through 104 microenterprises

- 300 handicraft artisans from cooperatives linked across 5 markets with an annual turnover of 30 lakh. 25% average increase in annual income of these artisans

SDG linkage

Promoting water conservation

Developing community managed water ecosystems

Impact

- 50 mn cubic feet ground water recharge potential created

- 478 water harvesting structures created

- 495 community institutions formed to manage these water resources

- 420 hectares of land treated through soil and water conservation measures

- 1,58,068 lives from proximate households gained access to drinking water

SDG linkage

Promoting health through nutrition

Prioritising nutrition of women and children at the household level

Impact

- 14,685 kitchen gardens developed to fight nutritional deficiency, reaching 61,625 lives

- 6,850 pregnant women, mothers and adolescent girls reached through nutritional awareness sessions

- 662 malnourished children identified and followed up jointly with Anganwadi workers

SDG linkage

Improving public health

Ensuring that the burden of vector borne, and non-communicable diseases ceases to be a public health problem

Impact

- 666 youth trained on Vector Borne Disease (VBD) control

- 2,148 households covered with indoor residual spray for prevention of VBDs

- 7,452 women trained on self-breast examination

- 13% of the eligible population in panchayats, screened for Non–Communicable Diseases

SDG linkage

Supporting Persons with Disability (PwD)

By fostering self-reliance and a life of dignity for all PwDs

Impact

- 9,081 PwDs reached through SABAL

- 95% block saturation for disability certification attained in Noamundi and 35% in Jagannathpur

SDG linkage

Eliminating worst forms of child labour

in Jamshedpur through Masti Ki Paathshala

Impact

- 1,631 slum children reached and 381 children mainstreamed to different schools

- 65 slums in Jamshedpur covered through this initiative

- 46 residential and non-residential facilities functioning under Masti Ki Pathshala, with Tata ClassEdge systems.

SDG linkage

Promoting education through scholarships and special coaching

Facilitating education of rural children

Impact

- Jyoti Fellowship - 5,608 SC/ST students (65% females)

- Tata Steel Scholars - 128 children

- Akanksha Programme (PVTG community) - 336 children (55% females)

- Green School Project (environment awareness) - 16,757 children from 45 schools

SDG linkage

Building women leadership

To have an effective voice in community decision making

Impact

- 1,700+ women enrolled as a part of the DISHA project which is an effort to develop 6,000 women leaders

- 1,122 women participated in Gram Sabha

SDG linkage

Promoting sports

Identifying and developing sporting talent in rural youth

Impact

- 3,502 children/youth trained in sporting activities

- 1,506 trainees participated in different regional, state and national sporting events

SDG linkage

Creating rural infrastructure

For improved living standards

Impact

- 887 necessary public infrastructures created/renovated for community usage, reaching 1,90,497 lives

- Over 26,700 public infrastructures created/ renovated for community usage, reaching more than 2 lakh lives

SDG linkage

Embedding a societal perspective in key business processes and products

Employee volunteering

To address social issues in the communities we operate in

Impact

- 18,494 volunteering hours clocked

- 287 social issues addressed

SDG linkage

Social immersion

By engendering a cadre of business leaders who embody a societal perspective in their business decisions

Impact

- Building transformational future leadership by sensitizing future leaders towards vulnerability of proximate society and developing emotional intelligence in them, through rural immersion.

SDG linkage

Not applicable