We are India’s lowest cost producer of steel. Our history and journey are inextricably linked to the Indian growth story; and we have helped build the nation’s industrial narrative, since the time we laid the foundation of India’s first industrial city in Jamshedpur more than 100 years ago.

CAPACITIES

jamshedpur plant

kalinganagar plant

capacity of tata steel BSL

formerly known as bhushan steel

PRODUCTION AND SALES

CRUDE STEEL PRODUCTION

NEW PRODUCTS DEVELOPED

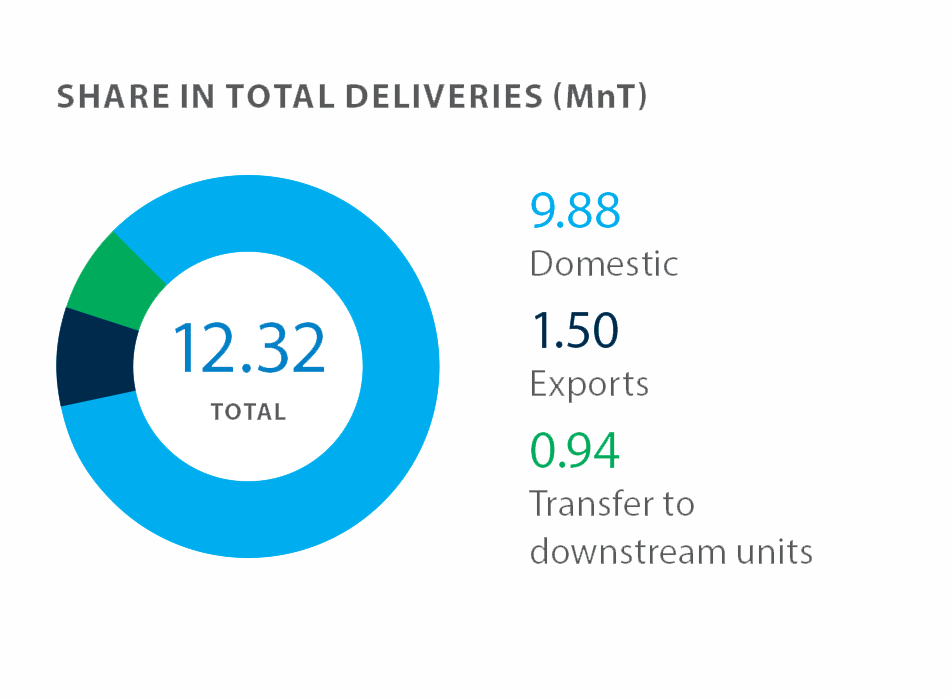

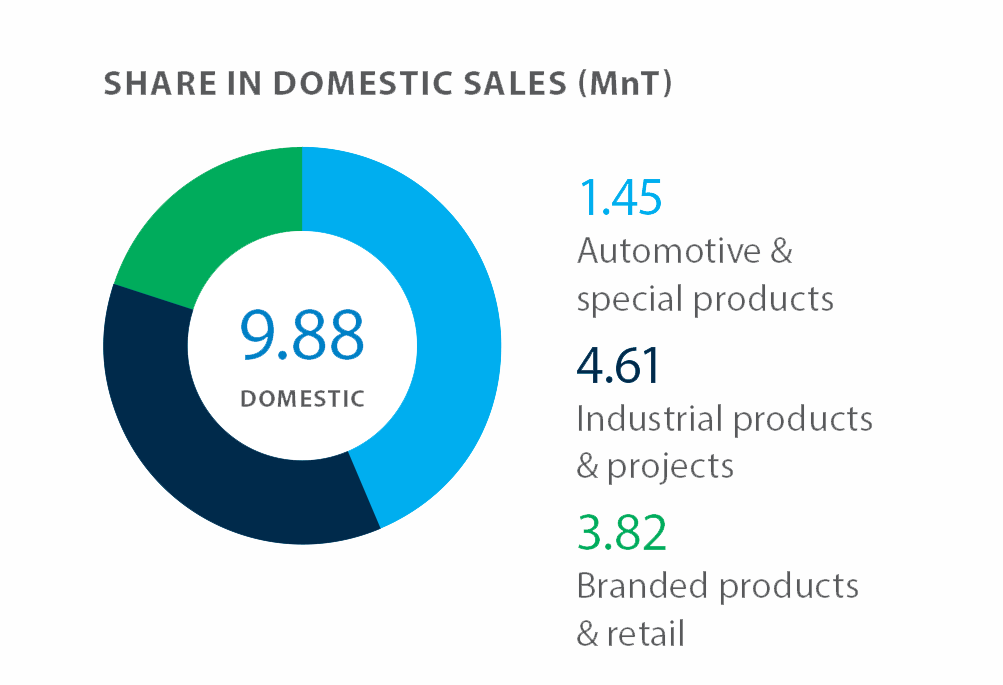

DELIVERIES

FINANCIALS

TURNOVER

EBITDA

PROFIT AFTER TAX

EBITDA/TONNE

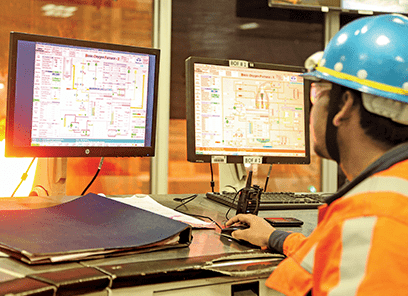

Tata Steel Kalinganagar is the first Indian plant to be included in the elite Global Lighthouse Network of the World Economic Forum for its leadership in applying Industry 4.0 technologies.

India’s first steam ageing facility for ‘accelerated weathering’ of LD slag was commissioned at Tata Steel Jamshedpur.

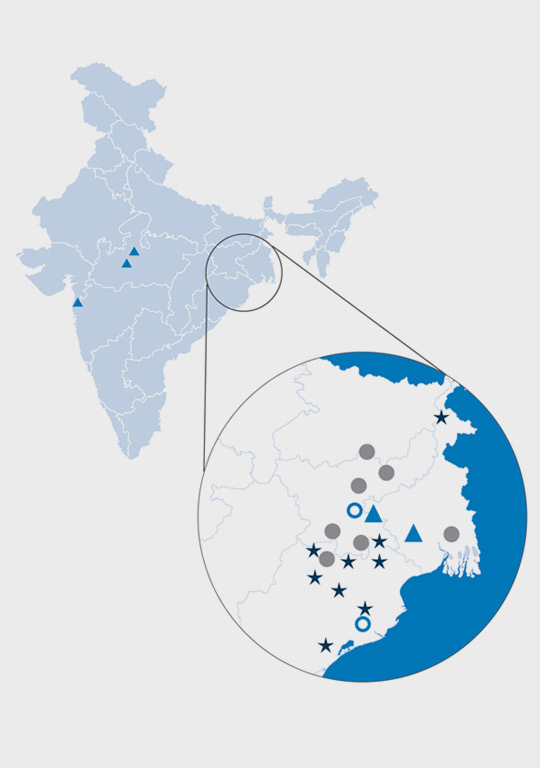

In India, Tata Steel operates integrated manufacturing facilities in Jamshedpur and Kalinganagar, with captive iron ore and coal mines, a dolomite mine, a chromite mine and manganese mines spread across Jharkhand, West Bengal and Odisha.

Raw materials

The making of steel depends on natural resources such as iron ore, coal and other minerals, which constitute our key raw materials. Our steelmaking operations at Jamshedpur and Kalinganagar secure 100% of their iron ore requirement from captive sources and this remains one of our biggest operational strengths. It helps us maintain cost-competitiveness and derive production efficiencies, while insulating us against volatility in the open market.

Ferro Alloys and Minerals Division

jamshedpur

kalinganagar

DHENKANAL

jamshedpur

Tubes manufacturing and tinplate

tarapur, pithampur, killa

Wire manufacturing

Kharagpur

Bearings manufacturing

noamundi, joda east, katamati, khondbond

Iron ore mines and quarries

west bokaro

Open cast coal mines

jamadoba group, sijua group

Underground coal mines

joda, bamnipal, gopalpur

Ferro alloys plant

joda west, bambebari, malda, tiringpahar

Manganese mines

sukinda

Chromite mine

gomardih

Dolomite mine

Asia’s first integrated steel plant

Tata Steel Jamshedpur (TSJ) is our flagship facility. From driving the first stake into the soil of Sakchi village in 1908 to becoming India’s steel city, Jamshedpur (also known as Tatanagar) is the soul of the Tata story.

An industry benchmark

TSJ sets the yardstick for specific consumption of energy, refractory, pulverised coal injection and coke rates in India

Initiative to roll out process safety through a ‘Centre of Excellence’ methodology at Jamshedpur has been appreciated by World Steel Association as the ‘Best Practice’ of 2018 across the industry

Availability of critical manufacturing units

Our focus on asset management using data analytics and predictive modelling, has resulted in >90% availability of our key manufacturing units at Jamshedpur.

Key outputs

Hot rolled coils

Cold rolled coils

Wire rods

Galvanised coils

Rebars

India’s largest single-location

greenfield steel project

Tata Steel Kalinganagar (TSK) is our second integrated steel plant in India, manufacturing high-end flat products. Spread over 3,000 acres and commissioned in 2016, TSK attained production levels at its rated capacity in less than two years. We installed state-of-the-art equipment and modern facilities to achieve a highly cost-competitive and productive plant. TSK is designed to have a minimal water as well as carbon footprint.

Key digital enablers

High-speed data extraction

Predictive maintenance deployment

3D printing

Data-backed decision- making and real-time monitoring

Advanced analytics

Artificial intelligence modelling

Key operational highlights

Fortifying tomorrow

Following the successful implementation of Phase I of the Kalinganagar Project in Odisha, we initiated the next phase of capacity expansion in Kalinganagar in FY 2018-19.

The project configuration and costs include investments in raw material capacity expansion, upstream and mid-stream facilities, infrastructure and downstream facilities. This will help us make value-added products like cold rolled galvanised and annealed products, as well as meet the requirements of automotive, general engineering and other high-end quality product market segments.

capex allocation

capacity expansion

expected project completion

Tata Steel is home to a comprehensive portfolio of products

and brands, catering to multiple industries and segments.

From the vehicle you drive, to the house you live in; from the

bridges you cross, to the hand tools that you use; the steel we

produce is an integral part of your everyday life.

SEGMENT

Market Sub-segments

Individual House Builders (B2C)

Corporate and Government Bodies (B2B)

(B2G)

Infrastructure (B2B)

Housing and Commercial (B2ECA)

Products and brands

Tata Tiscon (rebars), Tata Pravesh (steel doors and windows), Tata Shaktee (roofing sheets), Tata Pipes (plumbing pipes), Tata Structura (tubes)

Habinest (prefabricated houses), AquaNest Water Kiosks, Ezynest Modular Toilets, MobiNest (office cabins), Nestudio (rooftop houses), CanvaNest (EV charging station), Smart Easy Nest (for smart cities)

TMT rebars (higher dia rebars and corrosion-resistant steel)

Tiscon readybuild (cut and bend bars), Tata Structura (tubes), PC Strands (LRPC)**, Tata Nirman, Tata Aggreto, Ground Granulated Blast Furnace Slag (GGBS), WAMA – GC for walling

SEGMENT

Market Sub-segments

Auto OEMs* (B2B)

Auto Ancillaries (B2B) (B2ECA)

Products and brands

Hot-rolled (HR), Cold-rolled (CR), Coated Coils and Sheets

HR, CR, Coated Steel Coils and Sheets, Precision Tubes, Tyre Bead Wires, Spring Wires, Bearings

SEGMENT

Market Sub-segments

Panel and Appliances, Fabrication and Capital Goods Furniture (B2ECA)

LPG (B2B)

Welding (B2B)

Transmission Power and Distribution (B2B)

Process Industries (Cement, Power) (B2B)

Products and brands

Tata Steelium (CR), Galvano (Coated), Tata Astrum (HR), Tata Structura (tubes), Tata Astrum Super (for fabrication)

Hot-rolled (HR)

Wire rods

Tata Astrum Super (for fabrication)

Tata Tiscrome (ferro chrome), Tata Ferromag (ferro manganese), boiler tubes, Tata Pipes, Tata Ferroshots, Blast Furnace (BF) slag, Metallics

Notes: B2B – Business to Business;

B2C – Business to Consumer;

B2G – Business to Government;

B2ECA – Business to Emerging Corporate Account

*OEM – Original Equipment Manufacturer

**LRPC – Low-relaxation Pre-stressed Concrete

SEGMENT

Market Sub-segments

Agri Equipment (B2B)

Fencing, Farming and Irrigation (B2C)

Products and brands

Bearings

Galvanised Iron (GI), Wires, agricultural and garden tools, conveyance tubes

The trust that Tata Steel has garnered in the past 110+ years is an irreplaceable asset created through the efforts of colleagues. Our leaders guide us towards a better tomorrow, as we take this legacy forward and seek opportunities to create new value in the age of accelerating change.

standing (left to right)

T. V. Narendran

Chief Executive Officer and Managing Director

V. K. Sharma

Non-Executive Director

Petrus Blauwhoff

Independent Director

Deepak Kapoor

Independent Director

Saurabh Agrawal

Non-Executive Director

Koushik Chatterjee

Executive Director and

Chief Financial Officer

sitting (left to right)

Aman Mehta

Independent Director

N. Chandrasekaran

Chairman

Mallika Srinivasan

Independent Director

O. P. Bhatt

Independent Director