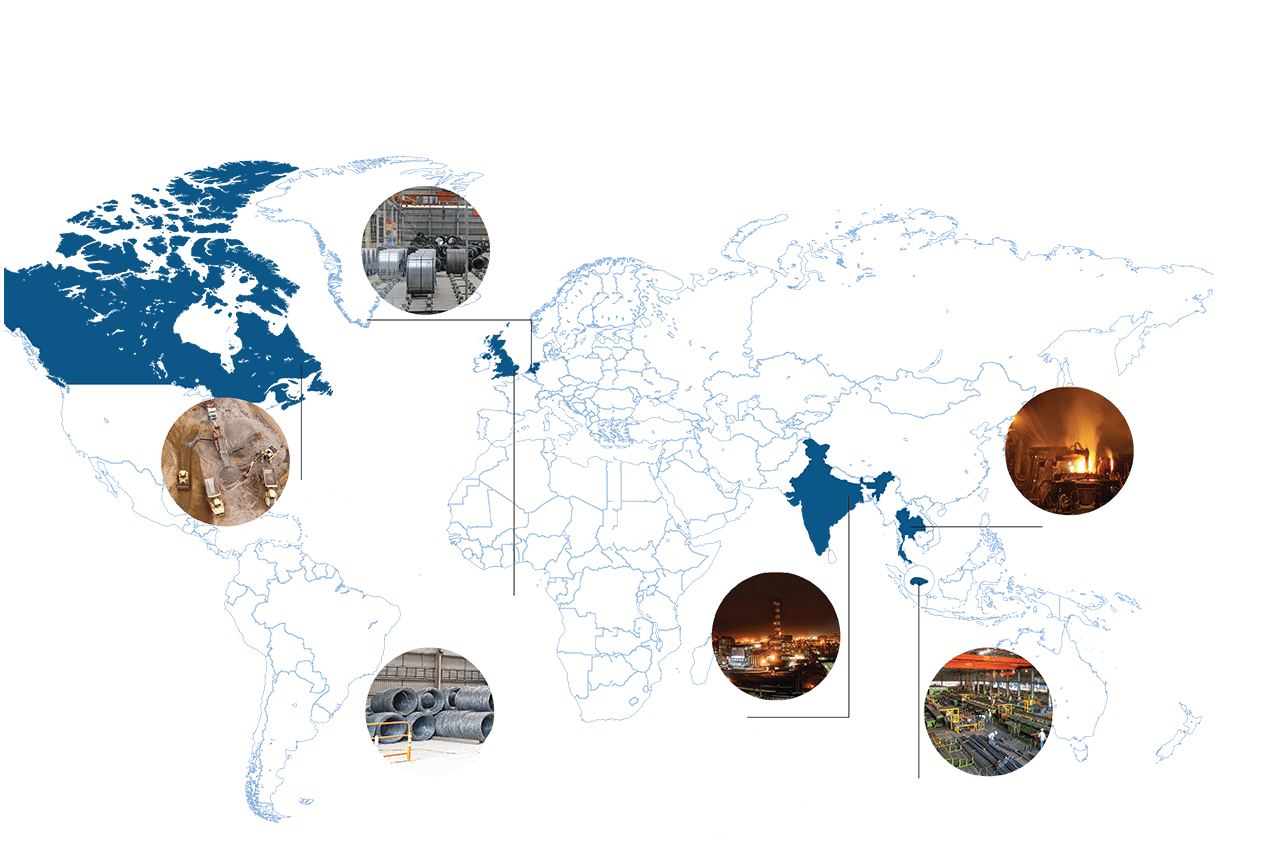

Tata Steel is one of the world’s most geographically diversified steel producers. With raw material operations in India and Canada, and manufacturing units spanning India, Europe and South-East Asia, we are self-sufficient in iron ore.

CAPACITIES

GLOBAL CRUDE STEEL

FINANCIALS

TURNOVER

PROFIT AFTER TAX

PRODUCTION AND SALES

STEEL PRODUCTION

DELIVERIES

NOTE: ALL FIGURES ARE FOR FY 2019-20 (CONSOLIDATED)

Did you know?

Tata Steel is what connects the London Eye, Kolkata’s Howrah Bridge and Dubai’s Burj Khalifa. All three iconic structures have been built using our steel.

Our steel is found in every model of Boeing and Airbus civil aircraft in production today.

90,000 sq m of our steel, equal to almost 17 football fields, is building the new gem in London’s skyline, 100 Bishopsgate Tower.

Recognitions

The Tata group’s value system directs the growth and business of all sectors we operate in.

Mission

Consistent with the vision and values of our founder Jamsetji Nusserwanji Tata, Tata Steel strives to strengthen India’s industrial base through effective utilisation of staff and materials.

The means envisaged to achieve this are cutting-edge technology and high productivity, consistent with modern management practices.

Tata Steel recognises that while honesty and integrity are essential ingredients of a strong and stable enterprise, profitability provides the main spark for economic activity. Overall, the Company seeks to scale the heights of excellence in all it does in an atmosphere free from fear, and thereby reaffirms its faith in democratic values.

Vision

We aspire to be the global steel industry benchmark for Value Creation and Corporate Citizenship.

We make a difference through:

Our People

Our Offerings

Our Conduct

Our Policies

Our Innovative Approach

Values

Our excellence is rooted in the value system of the Tata group.

Tata Iron & Steel registered as a company

Obtained first colliery for Tata Iron & Steel, adding six more in the course of time

Began successful operations of first blast furnace

Rolled out first ingot of steel from the Sakchi

plant; introduced an

8-hour working day

Established India’s first steel (coke) plant on June 18, as an enterprise financed by Indian capital and built by Indian workers

Signed agreement with Kaiser Engineers for a 2 MnT expansion programme

Acquired the London-based steel manufacturer Corus Group, thereby becoming one of the most geographically diversified and leading steel producers in the world

Commemorated 100th year, with the Indian Prime Minister unveiling the centenary postage stamp

Created history by becoming the world’s first integrated steel company to be awarded the Deming Grand Prize

Began commercial production in Kalinganagar, our second integrated steel plant in India

Acquired Bhushan Steel

Undertook second phase of capacity expansion programme at Kalinganagar

Acquired Usha Martin’s steel business through our subsidiary, Tata Sponge Iron Limited

Tata Steel Mining Limited signed 50-year leases for Kamarda and Saruabil chromite mines

<drag to preview>

Established in India as Asia’s

first integrated private steel

company in 1907, Tata Steel,

today, has flourished across

five

continents. Continuous

improvement in our product

and

service portfolio, along

with success in value-added

services for

customers,

allows us to serve global

growth markets.

We are Asia’s first integrated steel company with captive iron ore mines and collieries located near our manufacturing facilities in Jamshedpur and Kalinganagar. With a slew of organic and inorganic growth initiatives, we are strengthening our business in India and remain well poised to take advantage of the emerging opportunities in the country.

Jamshedpur

Our flagship facility and Asia’s first integrated steel works

Kalinganagar

India’s largest single-location greenfield steel project

DHENKANAL

Tata Steel BSL’s plant is one of India’s largest integrated steel mills equipped with steelmaking and finishing facilities

One of the most profitable and lowest

cost producers of steel in the world.

crude steel capacity

capacity of tata steel bsl

formerly known as bhushan steel

Tata Steel is Europe’s second-largest steel producer, establishing a presence in the continent after acquiring Corus in 2007. We have integrated steelmaking sites in Ijmuiden, the Netherlands and Port Talbot, the UK. Our other downstream facilities across Europe produce a variety of special steels, ultra-pure re-melted steels and various rolling and coating lines.

Ijmuiden, the Netherlands

Known for producing high-quality steel used in automotive, construction, packaging, batteries, tubes, industrial vehicles and white goods

Port Talbot, the uk

Part of the strip product business of Tata Steel in the UK

A new high-tech robotic welding line, the largest in the UK, has been introduced at the automotive service centre in West Midlands.

crude steel production capacity

of the uk’s steel requirements supplied by tata steel uk

Our South-East Asian operations began in 2004 with the acquisition of NatSteel, Singapore. This was further strengthened in 2015, when we acquired a majority stake in the Thailand-based steelmaker Millennium Steel. We are concentrating our efforts in the region to grow our value-added products and services portfolio, while strengthening our key steel operations in Singapore, Thailand and China.

natsteel, singapore

One of the best steel producers of Singapore

tata steel thailand

Largest producer and distributor of long steel products in Thailand

operating capacity

of scrap from city consumed in plant

rolling (finished) capacity

of steel exported to global destinations

Tata Steel Minerals Canada is a JV between Tata Steel Limited (80%) and New Millennium Iron Corporation (20%). The JV aims to develop iron ore deposits in Quebec, and Newfoundland and Labrador in Canada and is involved in two major projects.

Direct Shipping Ore project

Involves mining, crushing, washing, screening and shipping the sinter fines and pellet fines to Tata Steel’s European steel-making facilities

Taconite project

Conducting a Feasibility Study of the LabMag and KeMag iron ore deposits, which form a part of the 150-km-long Millennium Iron Range in northern Canada.

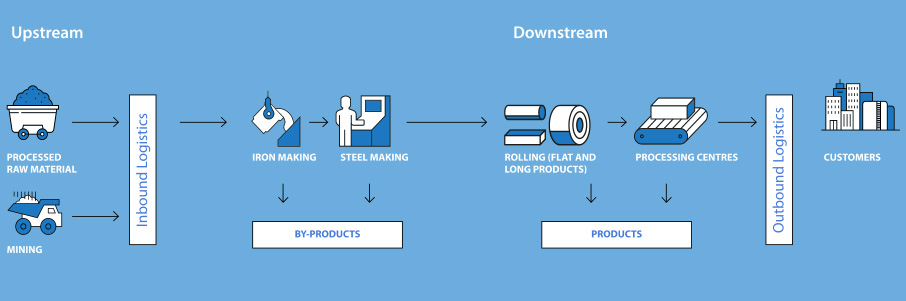

Tata Steel is one of the few fully-integrated global steel producers,

involved across mining, iron- making, steel-making,

casting, rolling and finishing,and marketing and sales.

Mining

We adopt a holistic operating model encompassing a steel value chain and a raw materials value chain, along with downstream and allied businesses related to value-added products and solutions.

Manufacturing

We convert the raw materials to hot metal and crude steel through various supporting processes, including coke making, sinter making and pelletisation. On the one hand, the steel is cast into slabs, which are then rolled into flat products. On the other, the steel is cast into billets, which are then rolled into long products.

Marketing

We cater to an array of market segments in countries across the world with products and brands that fulfil different requirements.