Report Menu

Report Menu

People

People are one of the most valued stakeholders for Tata Steel and we have institutionalised policies that lay the ground for right opportunities for our workforce, while ensuring their health, safety and well-being. We aim to nurture the future leadership of the Company.

The megatrends shaping up the global workspace are around enhancing employee experience, learning and innovation, diversity at the workplace and digitalisation. Our efforts are to work towards tapping these trends and leveraging our immense human capital to make the best use of these emerging trends and add value to the processes and the organisation at large.

Tata Steel has been a front-runner in people practices. The impetus now is to take the legacy forward, while the intent is to bring in new practices and keep ahead of the changing demography and needs of the future workforce. Safety and health of our employees is our top priority.

Promoting diversity

Safety line walk by the leadership team: Making safety part of our culture

Safety and Health

KEY

AREAS

SO4, SG3

- Contractor safety risk management

- Excellence in process safety management

- Eliminating incidents on rail and road

- Competency for hazard identification and risk management

By its very nature, the steel industry is hazardous due to hot processes and moving equipments. Hence, leadership at Tata Steel gives top priority to the safety and health of the entire workforce. Safety and Health Management is integrated into our Annual Business Plan (ABP) and cascaded into the annual Key Result Areas (KRAs) of each executive, which is linked to remuneration, to place accountability and responsibility at all levels. Linking safety targets to remuneration and visible commitment from the Senior Management has led to the inclusion of safety into our culture and behaviour. We are ‘Committed to Zero’ harm. Our safety systems also focus on the contractor workforce who are semi-literate, less skilled and more exposed to safety hazards.

We have a Safety and Health Governance structure for guiding and reviewing the Safety and Health performance, both at the Board and Company levels. The SHE Committee of the Tata Steel Board (chaired by an Independent Director) and the Apex Safety Council (chaired by the Chief Executive Officer and Managing Director) meet on a quarterly basis. The Apex Safety Council Meeting is attended by the relevant Vice Presidents (VPs) for key decision making on our ‘Commitment to Zero’ harm. These directives are cascaded through six Apex Safety Sub- Committees chaired by the VPs of all the relevant functions, through monthly reviews. Divisional Implementation Committees (DICs) and Area Implementation Committees (AICs) facilitate the implementation of policy decisions at the grassroots level across all functions in the organisation.

Key Enablers and Initiatives

1. Build (safety) leadership capability at all levels to achieve zero harm

As part of the Safety Leadership Development, Felt Leadership Training has been completed for 4,060 officers so far. Felt Leadership Training has also started for Tata Steel’s associated companies for improving their safety culture.

impact created

- 20% reduction in LTI cases –Improvement in safety performance

- Departments with more than 100 employees recording zero LTI have increased to 50 in FY 2017–18 from 42 in FY 2016–17 for Tata Steel India

2. Improve competency and capability for hazard identification and risk management

To ensure the engagement of trained front-line leaders in identifying hazards and mitigating the risks, a new Job Cycle Check (JCC) system has been developed on the existing Company-wide IT-based ‘Ensafe’ platform. It aids the revision of Standard Operating Procedures (SOPs) for critical hazardous activities, which are known as Red SOPs. As part of skill development of contractor employees, focussed training programmes have been started.

impact created

- 1,223 (67%) out of 1,818 identified SOPs for critical hazardous activities have been revised to ensure a safe workplace

- 183 contractor supervisors and 1,372 contractor workers have been trained and certified in various categories as part of skill development

3. Contractor safety risk management

To ensure the deployment of competent vendors for high-risk jobs, Star-rating assessment was conducted for all high-risk vendors.

impact created

- 40% reduction in contractor fatalities and 21% reduction in LTI cases of contractor employees as a result of multiple initiatives

4. Elimination of safety incidents on road and rail

For deployment of traffic segregation and density reduction, infrastructure improvement projects have been deployed. Heavy vehicle simulators have been installed to facilitate improvement in the competency of heavy vehicle drivers operating within Tata Steel, Jamshedpur.

impact created

- Sustaining zero fatality on roads across Tata Steel India for three consecutive years

5. Excellence in Process Safety Management (PSM)

Five high-hazard departments - namely two steel melting shops (LD1 and LD2), one blast furnace (IBF) and the Cold Rolling Mill and By-Product Plant at Jamshedpur - have demonstrated excellence in PSM. These departments have been declared as Centres of Excellence (CoEs) based on internal assessments.

Achieving sustenance of CoE departments and rolling out of CoEs in other high-hazard departments, while improving the deployment of the Management of Change standards, are the key strategies under excellence in PSM.

impact created

- 7% reduction in total process incidences in FY 2017-18 over FY 2016-17

6. Establish industrial hygiene competency and improve occupational health

During the year, we upgraded our Occupational Health and Safety (OHS) IT system, implemented 12 hazard-control projects, strengthened the follow-up system through the Doctor @ Doorstep programme and enhanced focussed awareness and intervention programmes such as Doctor on line, theme-based awareness campaign, lifestyle management and stress management. To improve the competency among employees about emergency life support, refreshers training on first-aid and Cardio-Pulmonary Resuscitation has been initiated and 7,550 employees have been trained. 12,000 employees and contract employees have been covered in a theme-based health awareness campaign. During the year, we saw a 0.95% reduction in the health index over FY17 for which data has been analysed and corrective actions are being taken.

impact created

- 12 hazard-control projects implemented

Joint Departmental Councils: A culture of working together

Safety and Health

Way Forward

- Leadership training on updated risk matrix in India and South-East Asia facilities planned in FY 2018-19

- Skill improvement of contractor workforce and further improvement in the Star rating of high-risk job service providers to aid their employability and overall quality of life

- Implementing video analytics surveillance across the organisation in India along with road infrastructure improvement and introducing technology/digitalisation initiatives

- Strengthening Process Safety Management (PSM) – rolling out of PSM CoEs to nine new departments

- Implementation of identified industrial hygiene control measures in FY 2018-19 to achieve excellence in industrial hygiene – achieving 2% improvement in health index y-o-y

Our Performance

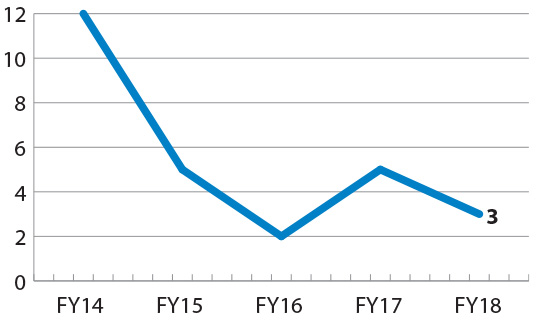

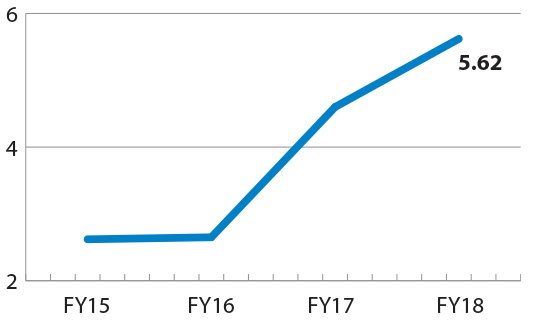

Fatality |

(Nos.) |

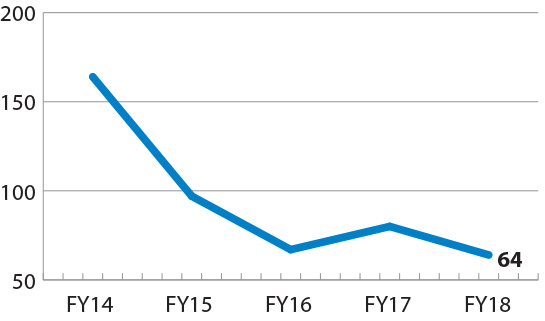

LTI |

(Nos.) |

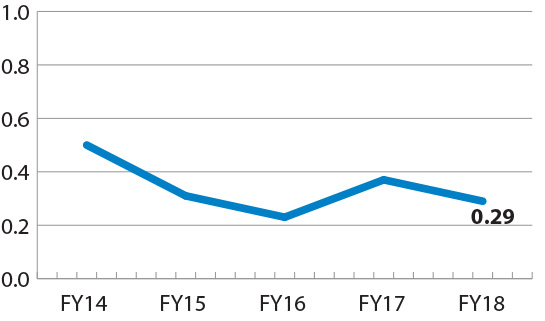

LTIFR |

(Rate) |

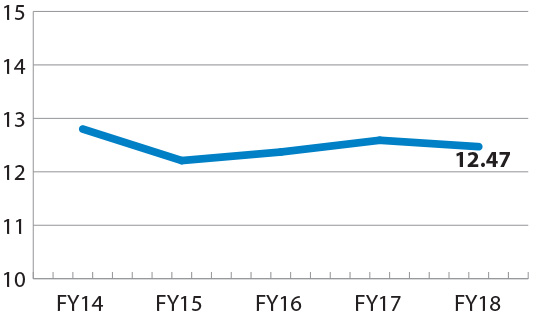

Health Index |

(Score out of 16) |

Tata Steel has been a front-runner in people practices with many pioneering policies. Our people practices are based on the Tata Values, with emphasis on respect, dignity and unity, fostering a culture of working together. These values have contributed in getting us to the top position in the core sector in the ‘Best Companies to Work for’ study for two consecutive years.

We are now trying to leverage the diverse demography in the country through inclusion of women, underprivileged sections of the community and specially-abled people. Industrial harmony of almost 90 years is a testimony to our commitment towards working together.

Employer of Choice

KEY

AREAS

SE1

- Productivity

- Diversity

- Capability Development

Gender inclusiveness

Heavy vehicle simulation training at safety excellence centre

Key Enablers and Initiatives

1. Improvement in Employee Productivity

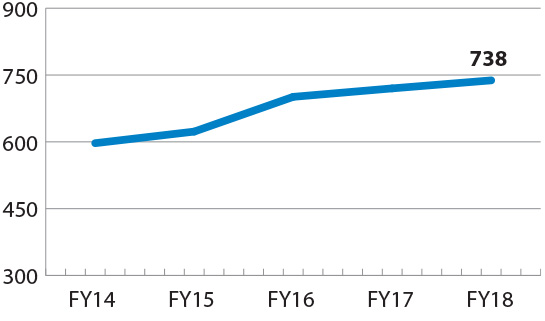

We strive to improve employee productivity of our workforce without compromising on industrial harmony. Our key enablers to improve productivity are adopting automation and technological interventions, reorganisation, restructuring and rationalisation. Revision in the voluntary separation scheme, Sunhere Bhavishya Ki Yojna (SBKY) with multiple options and Job for Job scheme are some of the key initiatives undertaken in this direction in FY 2017–18.

impact created

- Increase in employee productivity from 720 tcs/ employee/ year in FY 2016-17 to 738 tcs/ employee/ year in FY 2017-18 at Jamshedpur and from 653 tcs/ employee/ year to 918 tcs/ employee/ year at Kalinganagar.

tcs: Tonnes of Crude Steel

Enabling employee productivity

2. Diversity and Inclusion

MOSAIC – The Diversity and Inclusion initiative by Tata Steel defines the path we follow to celebrate and encourage diversity and inclusion through a five-pillar approach:

- Recruitment

In the context of hiring underprivileged and female candidates, the hiring authorities are encouraged to recruit the underprivileged or female candidate in the interest of diversity. Also, while sourcing CVs for hiring, incentives are given to head hunters who can source more diverse CVs for a particular position, all credentials and qualifications being the same. These efforts have also shown an increase in the numbers and percentage of women and underprivileged over the years. To encourage female employees especially in technical fields, a scholarship programme ‘Women of Mettle’ has been implemented. ‘Tata Steel Scholars’ is a programme for underprivileged candidates in which undergraduate students are chosen and mentored. Many of these trainees are then absorbed in the organisation.

- Development of Women Workforce

Several initiatives across the organisation have been implemented, with our focus on developing the women workforce and nurturing them as future leaders. These include, Tata Mentors, a programme for crosscompany mentoring for high-potential women executives trained by C-suite executives of other Tata companies, Reach Out, an opportunity for women leaders to learn and assimilate from leaders across India Inc., Tata Steel Engage, an internal women leaders programme, Tata Steel Ignite for emerging women leaders and Step Up to Success, a mentoring programme for female officers.

- Sensitisation

We have sensitisation programmes for C-suite executives, which include workshops on diversity for senior leadership, workshop on Power of Inclusive Management for middle management professionals and Zubaani, a platform for experience sharing by eminent speakers. - Supporting infrastructure

We have in place creches and rest rooms for female employees and accessible washrooms and other infrastructure for Persons with Disabilities (PwDs). - Celebration

We celebrate International Women’s Day and International Day for PwDs.

Inclusion of Persons with Disabilities (PwD) – Our efforts are directed towards establishing norms and practices that help create a more inclusive work environment for PwDs, with the first batch being inducted in FY 2017-18.

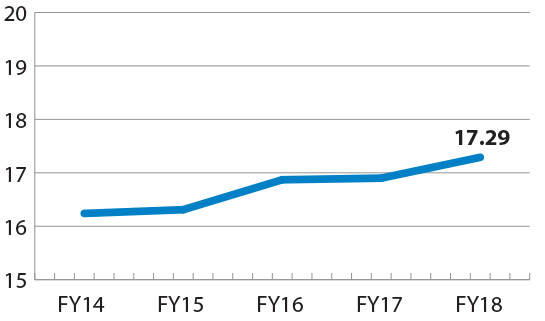

impact created

- Employees from the underprivileged communities form 17.29% of the total employees

- Around 40% of management trainees from top business schools are females

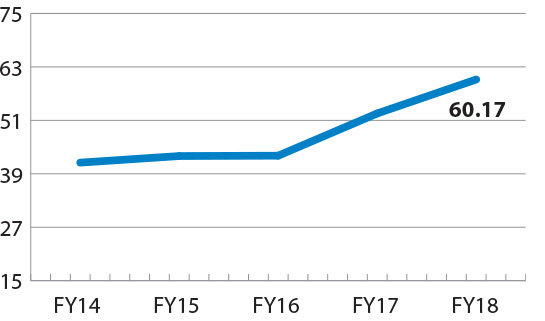

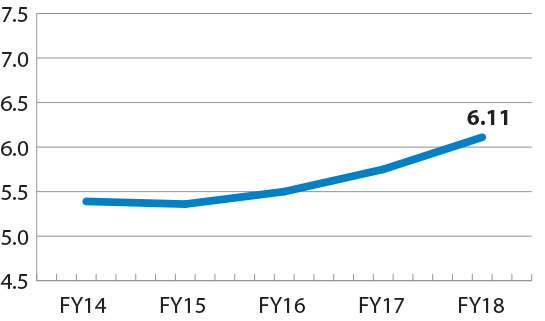

- Increase in the percentage of women workforce at all levels and overall from 5.21% to 6.11%

- Decrease in female attrition from 9% to 6% from FY17 to FY18

3. Capability Development

The capability development function has revamped its entire gamut of learning resources using digital technology and redesigned its training programmes to cater to the desired competencies of the entire workforce as per the business needs. E-learning modules have been rolled out with an aim to connect with approximately 80% of the workforce. Some key initiatives in this direction are:

- Design of 41 new programmes for contractor skilling, covering > 2,100 contractor workforce.

- Formation of Innovation Club, with 120 members, which provides financial and other support and covers more than 40 projects in areas spanning robotics, Internet of Things (IoT), waste management and alternative fuels.

- JN Tata Vocational Training Institute, which is run jointly by the Workers’ Union and the Company, aims to provide vocational training in various sectors to the youth of Jharkhand. The initiative intends to cover 3,000 youth by 2020.

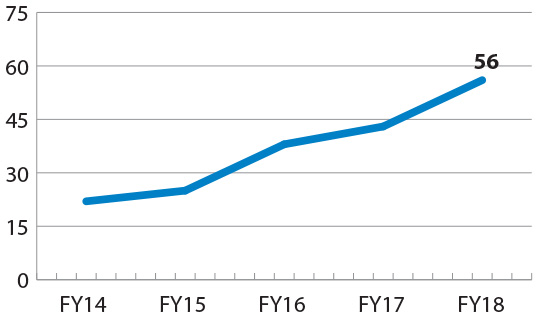

Our Performance

Training per employee |

(Man-days) |

Unique employees trained |

(%) |

Employees involved in |

|

Investment in employee |

|

Diversity – Women in the workforce |

(%) |

Diversity – SC/ST in the workforce |

|

Employee productivity - TSJ* |

(TCS/ Employee/ Year) |

Employee productivity - TSK* |

(TCS/ Employee/ Year) |

* Productivity calculations are based on the EOR of only the production departments, not the total EOR

Capability development: Training programmes for contractor employees

Employer of Choice

Awards

- We won the Avatar Award for top 100 organisations for women to work in 2016 and 2017.

- Tata Steel’s affirmative action has been appreciated many times by the Tata group’s Tata Affirmative Action Programme Award for its work in this domain.

- We won the Golden Peacock Award for HR Excellence in FY18.

Way Forward

Continuing our efforts to provide equal opportunities to a diverse workforce and nurture future leaders. To achieve this, we have set certain time-bound objectives for ourselves:

- Be an employer of choice in the top quartile across industries

- Increase productivity from 738 tcs/employee/ year to 900 tcs/ employee/year at Jamshedpur

- Aim to bring about 25% diversity in the workforce by 2025