Report Menu

Report Menu

Responsible Behaviour - ENVIRONMENT

A 3 MW solar power plant at Noamundi iron ore mine

Steel-manufacturing process depends on as well as impacts natural resources. Coal, iron ore, ferro alloys and water are key inputs to our iron and steel-making processes, resulting in emissions (e.g. CO2 , dust and other gases), discharge of effluents and solid waste generation. Due to our captive mines and collieries, we have a significant impact on the natural ecosystem and biodiversity in our mining locations. We are exploring the opportunities for increasing the utilisation of LD slag, which is a problem for steel manufacturers across the globe, through market-based solutions.

With consumer consciousness and community expectations growing in the area of environmental performance, we have begun to focus more on product stewardship and environmental declarations for our products.

Taking forward the learnings from the TSJ plant, the TSK plant has in place state-ofthe- art technologies and new facilities have been designed for minimal carbon and water footprint.

Butterfly park at Noamundi

Environment

KEY

AREAS

SO4, SG1, SG2

- CO2 emission

- Water consumption & effluent discharge

- Solid waste utilization

- Biodiversity

- Dust emission

Key Enablers and Initiatives

Responsible Behaviour: Environment

- Started Material Reclamation Plant (MRP) at TSK and upgradation of MRP at TSJ to recover metallic matter from LD slag and recycling

- Developed new markets/applications for LD slag

- Launched branded LD slag products – Tata Aggreto and Tata Nirman – in January 2018

- Year-on-year increase in the utilisation of LD slag (TSJ* and TSK figures are given below):

- FY 2015-16* – 43%

- FY 2016-17* – 53%

- FY 2017-18* – 59% (TSK – 56%)

- Avoided excess landfill

impact created

Responsible Behaviour: Environment

1. Sustain carbon efficiency in iron making

impact created

- Specific energy intensity (national benchmark)

- Sustained energy efficiency in FY 2017-18: 5.674 Gcal/TCS

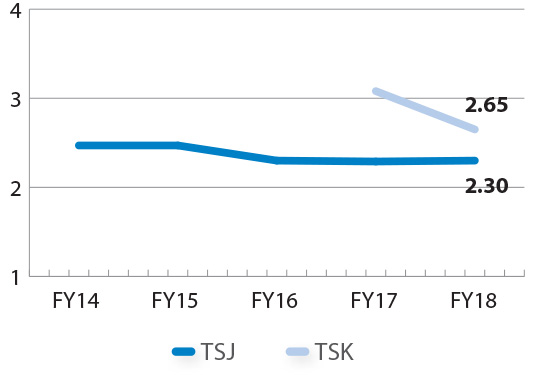

- Sustained CO2 emissions performance in FY 2017-18: 2.30 tCO2 /TCS

2. Integrate climate change mitigation into business decision making

Continued to implement internal carbon pricing (shadow price of CO2) in the financial appraisal of capital projects. One of the first Indian steel companies to do so.

impact created

- Fast-tracked environmental projects

- Directed investments towards low carbon growth

- Brand enhancement

3. TSK: Ramp-up Top Recovery Turbine (18 MW)

Commission CDQ (12 MW)

Start pulverised coal injection in 2017

Optimise fuel use due to ramp-up

- Over 0.6 MnTPA dry-quenched coke used by blast furnaces

- Used 3,58,723 t of Pulverised Coal Injection (PCI) in the blast furnace (123kg/t of hot metal)

- Reduced coke rate in blast furnaces to 434 kg/thm in FY 2017-18 versus

561 kg/thm in FY 2016-17 - Following ramp-up in FY 2017-18, 14% reduction in CO2 intensity at TSK

impact created

4. Raw material locations: Commission 3 MW solar power plant at

Noamundi

Use biodiesel in iron ore mines

- Generated 37,98,022 kWh solar power during FY 2017-18

- Used 18% biodiesel in Joda and Khondbond mines during October 2017

impact created

- Offset 3,038 tCO2 through solar energy

- 3% of the Renewable Purchase Obligations (RPOs) met through own generation in FY 2017-18

- Replaced 104 KL of diesel with biodiesel and offset 300 tonnes of CO2

Responsible Behaviour: Environment

1. Application in manufacturing of Portland cement, glass, mineral wool insulation, replacement of sand, etc.

Granulated and sold 98.5% of blast furnace slag to the cement plant to replace clinker by more than 60% in cement making

impact created

- Utilised 100% wet granulated slag in cement making, avoiding fugitive air emissions during transportation

2. Enhance value of products

GreenPro Certification awarded to Tata Steel’s GGBS by CII-GBC, Hyderabad. Tata Steel is one of the first companies in India to get the green product certification for GGBS. GreenPro is a CII-awarded green label that enables wider acceptance by environment-conscious customers

impact created

- Achieved highest-ever sales for GGBS of 16.5 KT, replacing equivalent quantity of Portland cement

3. Improve availability of processed slag and closely monitor and control effective utilisation of sinter plant assets

impact created

- Recycled ~98% of process-generated waste in the ironmaking process

Responsible Behaviour: Environment

Niche Nesting

Progressively implemented Biodiversity Management Plans (BMPs) at raw material locations in partnership with the International Union for Conservation of Nature (IUCN)

- Developed biodiversity management plans for each mining site

- Planted around 1,90,000 saplings of 45 species

- Installed over 400 nest boxes to enhance birds’ nesting niche at the Noamundi iron ore mine

- Used the globally recognised tool – Biodiversity Indicator and Reporting System (BIRS) for habitat enhancement monitoring and reporting

impact created

- Began systematic action, monitoring and reporting on biodiversity enhancement

- Promoted diversity in plantation and discouraged monoculture at each site

Reducing Freshwater Intake

Over the last decade, several initiatives have been taken at TSJ, including infrastructure upgradation for increasing water recycling and reuse and augmentation of rainwater harvesting within and beyond the fence. Apart from these, multiple improvement projects were undertaken, as listed below:

- Metering and on-line monitoring

- Departmental water audits

- Replacement of freshwater with recovery water in low-end applications

- Improved utilisation of recycling assets (Common Effluent Treatment Plant (CETP), effluent pumping and catch pits)

The major capital projects include commissioning of six catch pits and capacity enhancement of the existing catchment area.

impact created

- 35% reduction in water consumption in the last five years. At TSK, the focus has been on increasing water recycling through improvement in the CETP performance, improvement in Biological Oxygen Demand (BOD) treatment and better diagnosis of leakage and remediation at blast furnaces and hot strip mills

Reducing Dust Emissions

At TSJ, several improvement measures along with capital investment projects were undertaken to reduce dust emissions. These include upgradation of the existing Air Pollutant Control Equipment (APCE) and torch-cutting and fume-extraction system at Metal Recovery and Slag Processing Plant (MRSPP) commissioned in FY 2016-17 at `16.6 Cr.

impact created

- Maintained air emissions of TSJ at a level of 5 MnTPA while producing 10 MnTPA

Central effluent treatment plant: Reducing water footprint

Responsible Behaviour: Environment

Assessment of leasehold areas to monitor the biodiversity and habitat enhancements using the Biodiversity Indicator and Reporting System (BIRS) tool

Tata Steel and IUCN have been working together since July 2013 and phase-I of our engagement culminated with the launch of the Company-level biodiversity policy and the finalisation of Biodiversity Management Plans (BMPs) for each of the mining sites of Tata Steel. In 2016, Tata Steel entered into phase-II of engagement with IUCN for roll-out of BMPs at all mining sites.

In 2017, Tata Steel became the first company to monitor BMP implementation progress using the Biodiversity Indicator and Reporting System (BIRS) tool.

BIRS is a simple system for assessing the overall biodiversity suitability of a defined site having different habitat types, expressed as ‘Site Biodiversity Condition Class’, on a scale of 1-10. It considers the area of every habitat type on a site, the ecological condition of these habitats (including enhancements and threats) and the uniqueness and ecological importance of each habitat in the regional context.

A rise in the calculated index value and especially an increase in the Site Biodiversity Condition Class, from one assessment to the next, would show an overall enhancement of the suitability of a site for biodiversity, while a decrease would signal a lowering of the site’s value for biodiversity.

Assessment Review

- Feedback from the IUCN Regional Office and Country Office

- Feedback from the Tata Steel Senior Management

Key Development

Tata Steel conducted extensive BIRS assessments in 2017 at all mining sites. During the assessment, we identified site-specific key threats to biodiversity. Based on the BIRS report, Tata Steel is implementing measures to mitigate the threats, thereby contributing to the biodiversity enhancement of the site.

Way Forward

- BIRS will continue to be used for regular and standardised reporting on changes to biodiversity conditions

- Moving towards no net loss in biodiversity at its raw material location

IUCN: International Union for Conservation of Nature

Plantation in the mined-out area of hill 1 and 2 in Noamundi: Reducing the ecological footprint

Hibiscus park at Noamundi

Noamundi iron ore mine

Responsible Behaviour: Environment

Increasing the utilisation of by-products, especially LD slag, and introducing branded by-products, Tata Aggreto and Tata Nirman

The objective of our Industrial By-product Management Division (IBMD) is to deliver maximum value from our industrial by-products.

Exploring the Opportunities of a Circular Economy: Last year, IBMD processed ~13 MnT, of which ~6.8 MnT is slag from iron and steel-making. 18% slag was utilised internally in sinter making and another ~62% was used externally, mostly in cement making, reducing CO2 emissions from clinker making while conserving natural resources (limestone). We are currently exploring strategies and avenues to bring back the balance 20%, which is mostly steel-making slag, as part of a circular economy.

The steel-making slag is finding application in other industries such as cement, civil construction, road-making, railway ballast, etc. Our intent is to standardise processing to deliver consistent product specifications to make them suitable for various external applications.

We have achieved the highest ever steel-making slag utilisation during the year at TSJ at the rate of 59%. We have successfully derived value from various streams of by-products and maximising this presents a great opportunity.

Deriving value from by-products

Achieved

Launched branded LD slag brands:

- Tata Aggreto was launched in January 2018 for the sale of steel-making slag with a promise to provide superior, ready-to-use material with consistent sizes. This product replaces natural aggregate for road making. With the focus on road building in India, this could open up a new window for the Company.

- Tata Nirman was launched for usage as raw material in fly ash brick making (replacing sand as filler and limestone as binder) and clinker making (replacing limestone to the quantity consumed).

Major initiatives pursued through partnerships for the future

- De-bottlenecking the present wet and dry cycle weathering facility at Galudih

- Open-steam aging at TSJ and TSK

- Closed-steam aging system at TSJ and TSK

- Dedicated testing lab at TSJ for quality control of Tata Aggreto

- Slag atomisation at TSK

Responsible Behaviour: Environment

Way Forward

To demonstrate environmental leadership in the short and long term, we will pursue time-bound actions directed at the following:

- Reducing carbon footprint across the value chain (< 2tCO2/tcs) by 2025

- Moving towards zero effluent discharge for Tata Steel India

- Moving towards world benchmark for specific water consumption at < 3 m3/tcs at TSJ

- Utilising LD Slag at 90% for Tata Steel India by FY23

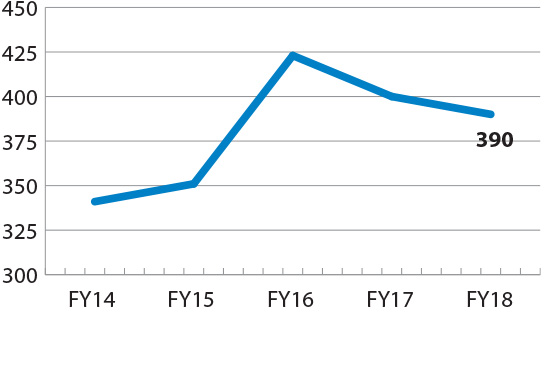

Our Performance

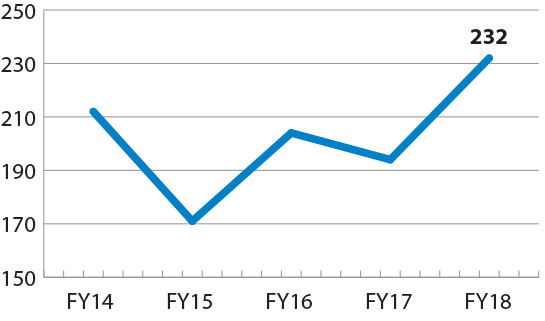

TSI – Trees planted |

(Thousand Nos.) |

Dip due to lesser availability of reclaimed land in mining areas

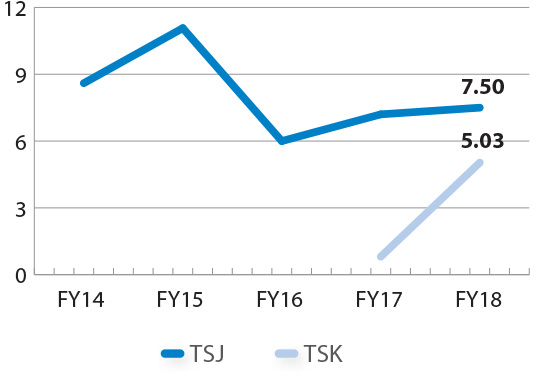

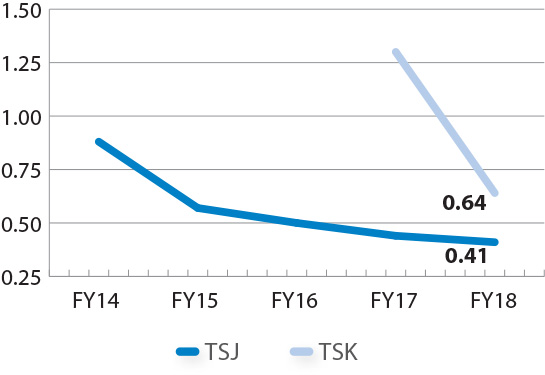

TSJ and TSK – Sulphur oxides (SOx) emission |

(kT) |

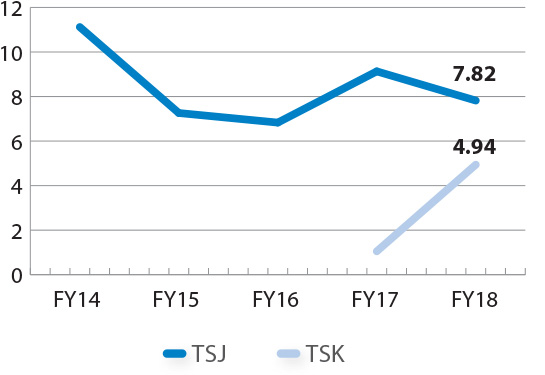

TSJ and TSK – Nitrogen oxides (NOx) emission |

(kT) |

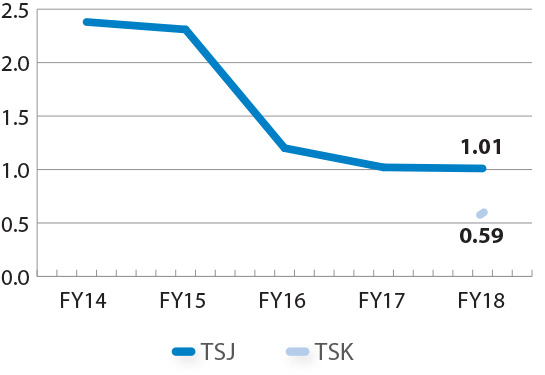

TSJ and TSK – GHG emissions intensity |

(tCO2e/tcs) |

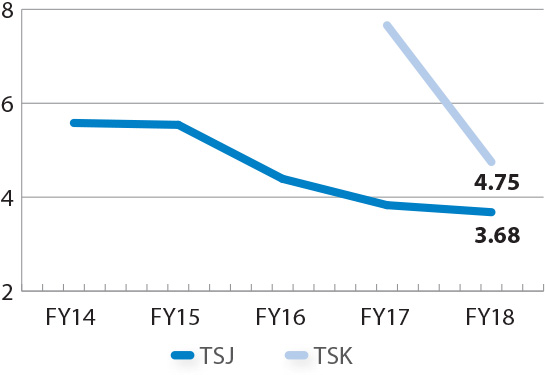

TSJ and TSK – dust emissions intensity |

(kg/tcs) |

TSJ and TSK – effluent discharge intensity |

(m3/tcs) |

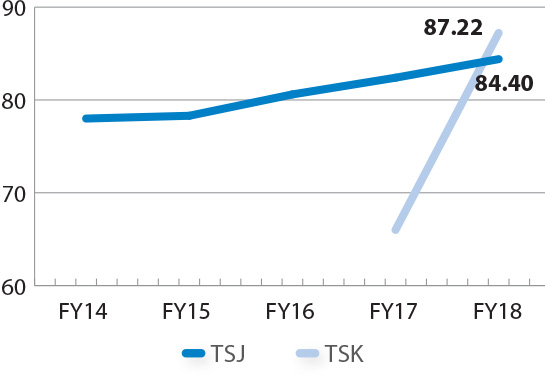

TSJ and TSK – Solid waste utilisation |

(%) |

TSJ and TSK – Specific Water Consumption |

(m3/tcs) |

| Steel-making sites (primary/ secondary) excl. downstream (as per worldsteel guidelines) |

Particulars | Absolute Emission |

|||||

|---|---|---|---|---|---|---|---|

| UoM | 2013-14 | 2014-15 | 2015-16 | 2016-17 | 2017-18 | ||

| India (TSJ and TSK) | Scope-1 | MnT CO2 | 20.46 | 21.10 | 21.02 | 25.53 | 26.33 |

| Scope-1.1 | MnT CO2 | 2.33 | 2.27 | 2.31 | 3.69 | 4.07 | |

| Scope-2 | MnT CO2 | 0.73 | 0.72 | 0.74 | 1.11 | 1.15 | |

| Scope-3 | MnT CO2 | -0.87 | -1.08 | -1.19 | -2.21 | -1.99 | |

| Overall | MnT CO2 | 22.65 | 23.02 | 22.89 | 28.11 | 29.55 | |

| Europe (incl. UK) | Overall | MnT CO2 | 27.79 | 26.96 | 25.48 | 19.27 | 19.18 |

| South East Asia (Tata Steel Thailand and NatSteel) | Overall | MnT CO2 | 0.98 | 0.91 | 0.98 | 0.91 | 1.01 |

Kalinganagar Steel Plant was commissioned in 2016-17 followed by ramp-up process

Responsible Behaviour - COMMUNITY

The first-ever tribal musical conclave, ‘Sarjom Baa’

The mining and metals business impacts the environment and communities around its area of operation. Our manufacturing and Raw Materials (RM) operations are in the eastern part of the country, having significant development challenges compared to the rest of the country.

Tata Steel actively engages with communities to respond to the development challenges in its operating areas through Corporate Social Responsibility (CSR) initiatives ranging across themes such as health, education and livelihood, along with initiatives in drinking water, sanitation, sports, empowerment, infrastructure creation and ethnicity. Our CSR approach is based on the needs assessed through community engagement. (Refer Page 23)

While addressing the major challenges faced by communities, we focus on signature programmes aimed at creating development models that can be replicated at scale and adopted across geographies with similar issues. Programmes such as Maternal & Newborn Survival Initiative (MANSI), enhancing school education and Samvaad are some examples of signature programmes that have been deployed in large geographies.

Community

KEY

AREAS

SO4, SG4

- Impact based CSR in areas of

- Health

- Education

- Skill development

- Sustainable livelihood

- Sports & Ethnicity

Key Enablers and Initiatives

Responsible Behaviour: Community / Rural

SABAL: Persons with Disabilities (PwDs) face discrimination and stigma in their lives (including from their own families and society) that restricts them in acquiring skills for a gainful employment

SABAL Centre for Abilities at Noamundi was created to empower PwDs through skilling programmes, which help mainstream them as well as sensitise communities to enable PwDs to lead productive and dignified lives. The centre is a joint venture of Tata Steel Skill Development Society (TSSDS) and Enable India.

impact created

- 28 PwDs empowered through training on skills

- 15 persons (including six PwDs) underwent the Training of Trainers (ToT) module in FY 2017-18

SABAL: Centre for Abilities

Empowering through skilling

Responsible Behaviour: Community / Rural

1. Enhancing School Education: To bring out-of-school children from vulnerable backgrounds in the fold of education and also to improve the foundation of learning in Government primary schools

The project intends to implement Right to Education by increasing the access of children to school, by improving the quality of primary education in Government schools as well as ensuring better governance through School Management Committees (SMCs).

impact created

- The initiative reached out to around 2,00,000 children across 2,800 habitations in Odisha and Jharkhand by the end of FY 2017-18

- 1,165 habitations have been made child labour free zones by the end of FY 2017-18

- In Odisha, school functioning has improved, with up to 90% attendance in some schools, regular PTA meetings, quality mid-day meals and active libraries, school projects, Bal Panchayats and children’s festivals

2. Residential Bridging Schools: To provide a safe and conducive residential school atmosphere to children from vulnerable backgrounds and link them to the formal education system

Tata Steel operates two all-girls schools at Pipla and Noamundi and an all-boys school (Masti Ki Pathshala) at Jamshedpur. The schools provide residential bridge courses for out-of-school children to re-integrate them into the formal schooling system.

impact created

- The three schools put together, 319 children have benefited in FY 2017-18

3. 30 Model Schools: To enable children from Educationally Backward Blocks (EBBs) to avail quality government educational infrastructure

Tata Steel has entered into a Memorandum of Understanding (MoU) with the government of Odisha to construct 30 Model Schools in 30 different blocks in the state to provide quality secondary education in EBBs. A total of nine Model Schools have been constructed and handed over to the state government so far, of which six were handed over in FY 2017-18.

impact created

- Benchmark infrastructure has facilitated proper environment for learning among over 5,000 rural children in the nine Model Schools

Improving the quality of education

Responsible Behaviour: Community / Rural

Vaarta: A farmer’s conclave to enable sustainability and profitability of agriculture

Productivity improvement in agriculture and allied activities: Agriculture is the mainstay for the population in Jharkhand and Odisha. However, due to lack of knowledge about scientific agrarian practices, many farmers in the two states do not consider agriculture and allied activities as full-time and profitable occupations.

Tata Steel adopts a multi-pronged strategy to promote sustainable livelihood options among small and marginal farmers. They are capacitated with new skills and knowledge to improve production practices through regular training programmes.

Scientific agrarian practices (System of Rice Intensification (SRI), multi-cropping, integrated cropping, etc.) and allied activities (pisciculture, lac culture, duck rearing, etc.) are also promoted among farmers. As dependence on rain limits the agriculture potential of the farmers in the two states, Tata Steel also provides them with irrigation facilities (ponds, check dams, etc.) that help increase cropping intensity.

impact created

- Increase in paddy yield by almost 1 tonne/acre

Responsible Behaviour: Community / Rural

1. Maternal & Newborn Survival Initiative (MANSI): Lack of easy access to institutional care (during pregnancy, delivery and post pregnancy) and low level of awareness about proper care for mothers and babies lead to mortality among neonates (less than 1 month old) and infants (less than 1 year old) in remote rural areas.

MANSI reduces mortality among neonates and infants by enhancing the capacity of Government health volunteers (ASHAs/Sahiyas) in the Home Based Newborn Care (HBNC) system. Tata Steel, the National Health Mission (NHM), American India Foundation (AIF) and the Society for Education Action and Research in Community Health (SEARCH) – the pioneer of HBNC in India – have collaborated in this public-private partnership, working in 12 blocks across Jharkhand and Odisha.

impact created

- Reduction in Neonatal Mortality Rate (NMR) – 61% since inception.

- Reduction in Infant Mortality Rate (IMR) – 63% since inception.

(Based on the study from the period January 1, 2015 to December 31, 2015)

2. Regional Initiative for Safe Sexual Health by Today’s Adolescents (RISHTA): Illiteracy and low level of awareness in rural areas lead to instances of early marriage and early parenthood, which have health-related as well as social and financial implications.

Project RISHTA enables adolescents to make informed choices about their sexual and reproductive health and overall well-being as well as provides coaching on life skills and self-development.

impact created

- Increased awareness about adolescent reproductive and sexual health in communities and improved overall health of adolescents by identifying and training peer educators among them (more than 700 developed in FY 2017-18)

- Reached out to 19,601 adolescents in FY 2017-18

- Launched the RISHTA mobile application for profiling adolescents in FY 2017-18

Providing institutional care to mothers, neonates and infants

Nurturing informed adolescents

Responsible Behaviour: Community / Rural

Samvaad - A Tribal Conclave

1. Samvaad: Tribal communities across geographies find deep roots in their traditional heritage, wisdom and culture, which often hold valuable insights for their identity as well as a sustainable way or life for the rest of the society. Hence, there is a need to preserve and promote this knowledge and enable their voices to be heard.

The annual tribal conclave, Samvaad, offers a platform for indigenous communities from India and abroad to discuss critical issues and showcase their heritage. Each year, Samvaad focusses on a specific theme centred around an area of interest for tribal communities. Samvaad also reaches out to a wider audience among tribal communities through Regional Samvaad events organised in tribal pockets across India. All events in Samvaad are attended by luminaries of national and international stature who have worked on aspects of tribal and social development.

impact created

- Regional Samvaad events held in 2017 at Wayanad (Kerala), Netrang (Gujarat), Guwahati (Assam), Amarkantak (Madhya Pradesh), Ranchi (Jharkhand) and Bhubaneswar (Odisha)

- Samvaad 2017 focussed on instilling leadership in tribal youth and was attended by many distinguished personalities working on development issues, including a Nobel Laureate

- Samvaad 2017 drew over 1,200 delegates representing tribal communities from India and abroad, with a firstever international flavour, with representatives of tribes from Australia, Canada, Kenya and Zimbabwe

- More than 400 tribal youth representing 103 tribes from 22 states went through a structured leadership programme during Samvaad 2017 that encouraged them to take leadership roles within their communities – these included around 100 youth engaged through a specially designed Tribal Leadership Programme earlier in 2017

2. Youth Empowerment through Sports (Football and Hockey): Communities residing in Tata Steel’s operational areas have a natural inclination and talent for certain sports (e.g. football and hockey). There is a need to discover and hone this talent, which could provide career options to rural tribal youth. Also, age-old tribal sports (e.g. Sekkor and Kati) that are integral to tribal heritage have lost their prominence over the years and therefore need to be preserved.

- To train budding football talent from remote locations of the Company’s operational areas, Tata Steel runs 31 under-10 football coaching centres.

- As part of the grassroots hockey development programme, Tata Steel operates 20 hockey centres in West Singhbhum, East Singhbhum and Seraikela-Kharsawan districts of Jharkhand.

- Hooking2Hockey involves training of students in the stick game through engaging modules; the programme implemented through 13 centres in Jharkhand and Odisha is designed by Hockey Australia, the governing body of hockey in Australia.

- Tata Steel consistently made efforts to revive and promote traditional tribal sports such as Kati, Sekkor, Chhur, Bahu Chor and Ramdel by organising tournaments among tribal communities in Jharkhand and Odisha.

impact created

- 22 cadets from the football and hockey training centres selected for sports academies (Minerva Punjab Academy, Chandigarh; United Sports Club Academy, Kolkata and Army Boys Sports Company-Bihar Regiment Centre- Danapur, an infantry of the Indian Army and Naval Tata Hockey Academy)

- 950 children covered under the grassroots hockey development programmes (including hockey centres and the Hooking2Hockey initiative) in FY 2017-18

- First-ever Sekkor Premier League drew 2,300 players from villages in Jharkhand in FY 2017-18

- The second edition of Kati Premier League drew 1,890 players from villages in Jharkhand and Odisha in FY 2017-18

- Total 55,963 youth engaged through popular sports and tribal sports

Responsible Behaviour: Community / Urban

1. Urban Amentities: Jamshedpur is the only million-plus city in India without a municipal corporation, with Tata Steel providing all amenities, such as power, water, sewage and sanitation, resulting in high Quality of Life (QoL) for its citizens. Tata Steel has ensured that the challenges posed by the surge in urban growth and aspiration for a world-class city with the best QoL in India have progressively been met. The Company consistently focusses on managing key urban amenities and resources efficiently and responsibly to make them available and affordable for the citizens. On metrics of QoL assessed by AC Neilson, Jamshedpur is neck to neck, and sometimes exceeding the likes of Chandigarh, with an eQ index of 88 and QoL index of 101 in FY 2017-18.

About 20 km of main roads have been de-congested through widening, including the creation of dividers, roundabouts and footpaths, over the last 3 years; 100% of streets are lighted.

impact created

- This drive was taken primarily to ensure safe and smooth flow of traffic in town. Similar such projects are underway in the current year as well

2. Green City: Jamshedpur is known for its parks and gardens, which are an integral part since the conception of the city.

Eight new parks have been created in the last 3 years.

impact created

- This has provided citizens an opportunity to be physically active and also reduces the Urban Heat Island Effect 37.54% – highest among industrial towns

3. Medical Services: Tata Steel runs a 1,000-bed modern tertiary-care hospital supported by eight Tata Memorial Hospital (TMH) clinics spread across Jamshedpur and has established a 200-bed Tata Steel Medical Hospital at Kalinganagar. TMHs are also located at Jamadoba, Noamundi, Sukinda, West Bokaro and Joda. These facilities meet the needs not only of the employees and their families, but also of the communities around our areas of operations.

Upgradation of all key infrastructure is in progress to meet the growing needs of the town and provide quality services. Adoption of NPS to capture customer feedback and actionable points for improvement has resulted in a perceptible improvement. The Company ensures extended availability of specialists and services to the community during the evening hours. Commenced TMH PRIME.

The team comprises over 2,000 trained professionals, including over 350 doctors, 700 nurses and 150 paramedics.

impact created

- 1.64 million OPD patients (including TMH clinics), 62,000 indoor admissions and around 19,000 surgeries and procedures

- TMH Prime has more than 67,000 OPD consultations, around 3,000 procedures and surgeries and 11,000 patients undergoing diagnostics

Our Performance

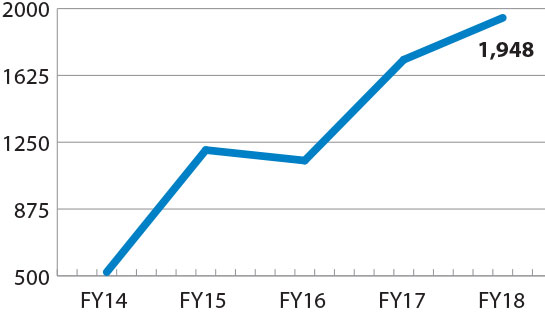

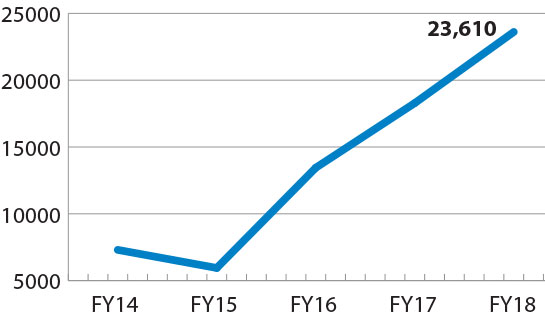

CSR spend |

(Cr.) |

Youth placed / self-employed |

(Nos.) |

Farmers covered through improved agricultural productivity |

(Nos.) |

Responsible Behaviour: Community/Sports

Sport

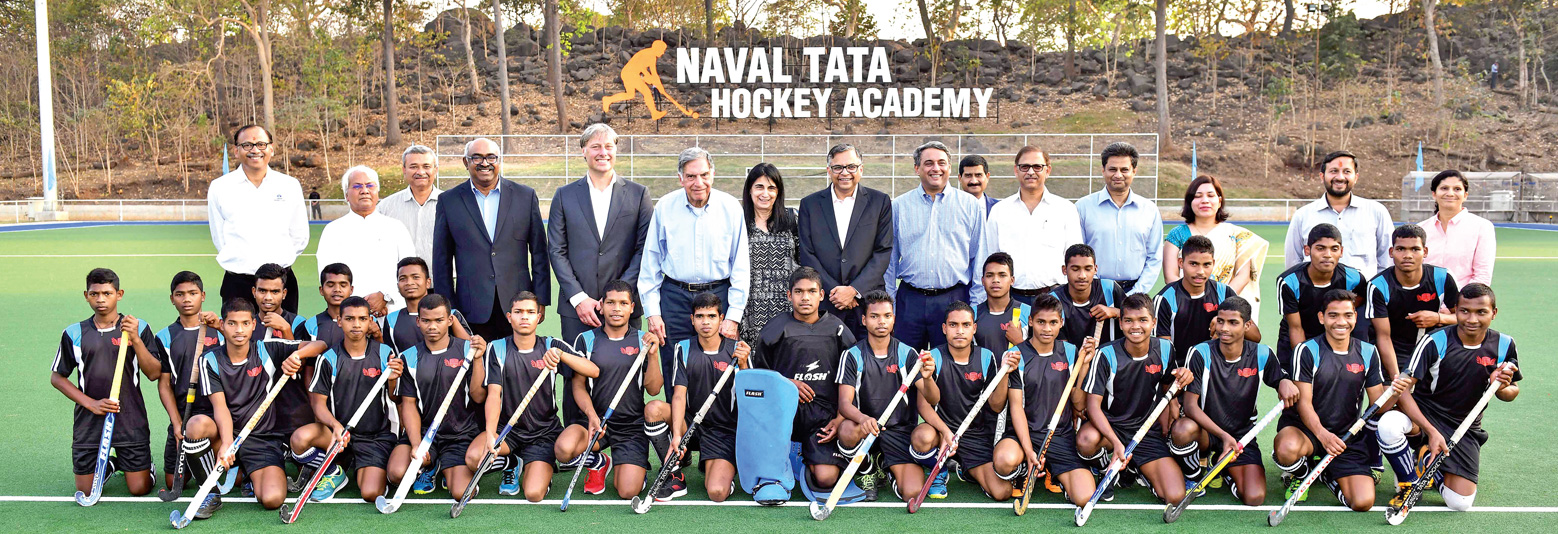

Naval Tata Hockey Academy: Providing a platform to budding sportspersons

Tata Steel engages employees, their families and the community in sporting activities. Tata Steel has been a promoter of sports – having built training centres for football, archery, hockey, mountain climbing, athletics, badminton, etc. The recent addition of a Tata-owned football club – Jamshedpur Football Club (JFC) – and matches of the Indian Super League (ISL) in Jamshedpur and Bhubaneswar have added to the sports orientation of the community.

1. Marathons

Tata Steel Kolkata 25K, a 25-km Run that has a social cause at its heart, supporting the Tata Medical Centre, a cancer hospital in Kolkata, was commenced four years back. Tata Steel has also organised running events in Jamshedpur and Noamundi (both in Jharkhand) and Bhubaneswar (Odisha).

impact created

- Seeing increasing participation, enhanced community connect through increased health consciousness

2. Naval Tata Hockey Academy Tata Steel and Tata Trust, along with Floris Jan Bovelander (Director of ‘One Million Hockey Legs’), joined hands in 2017 to promote hockey in the state of Jharkhand in a formalised way to form ‘The Naval Tata Hockey Academy’. The hockey stadium has a world-class astro turf for practice and tournaments. There is a special focus on the tribal community.

impact created

- From around 4,500 boys, 24 tribal boys were selected for the first batch

3. Tata Archery Academy

The Company continues to nurture the Tata Archery Academy. The Academy was established on October 4, 1996 with the aim to identify and train potential talented youth, particularly from Jharkhand, to achieve success at national and international meets. The cadets are provided a worldclass ecosystem – highest quality infrastructure and highly qualified coaches and support staff (including Strength and Conditioning Coach, Sports Psychologist, Nutritionist and Masseurs). The cadets are also provided with the highest quality archery equipment every year with an expenditure of ₹1.5 lakh per cadet.

impact created

- Over the last 16 years, the Academy has trained 127 cadets, 45 of whom have represented India at various levels. Its most popular student is Deepika Kumari, who has made it to the world’s top ranks in the sport. The Academy has an enthused community that identifies closely with the sport of archery.

4. Tata Football Academy (TFA)

TFA was established in 1987 to train and nurture budding Indian footballers. TFA identifies and shortlists raw talent from all over the country. Selected candidates join up for a four-year residential programme. The Academy is now reaping the benefits from linkages with JFC.

impact created

- Till date, of the 213 cadets graduated from TFA, 141 have represented the country. TFA cadets have also captained the Indian football team (in different age groups) and two former cadets have won the Arjuna Award. There are 28 ex-cadets participating in the current season of the ISL

5. Tata Steel Adventure Foundation (TSAF)

Established in 1984 and headed by Bachendri Pal, India’s first woman to climb Mt. Everest, the TSAF is all about promoting the spirit of adventure and enterprise and leadership development. Not less than seven TSAF beneficiaries have managed to conquer Mt. Everest.

impact created

- TSAF works with rural youth; more than 3,000 of them have benefited from TSAF’s outdoor leadership programme. It has helped several enterprising mountaineers, including Premlata Agarwal, who became the oldest Indian woman to climb Mt. Everest at 48 years of age. Arunima Sinha, who lost her leg in a train accident, became the first female amputee in the world to climb Mt. Everest.

6. Jamshedpur Football Club (JFC)

Tata Steel formed the JFC with Jamshedpur as the host city and participated in the ISL. The team brought together some of India’s top talent, promising youngsters and experienced foreign players. Tata Steel has shown its seriousness by upping its budget for football from ₹20 million a couple of years ago to around ₹300 million now.

impact created

- The larger intent behind JFC is to enhance the overall ecosystem of football, including grassroots football, youth football and women’s football, and to help improve the infrastructure and training and development practices in the game. There is overwhelming excitement and support from the community.

Tata Archery Academy

Tata Football Academy

Jamshedpur Football Club (JFC)