Intellectual Capital

Intellectual capital represents organisational knowledge-based intangibles.

Approach

Our intellectual capital is evidenced through:

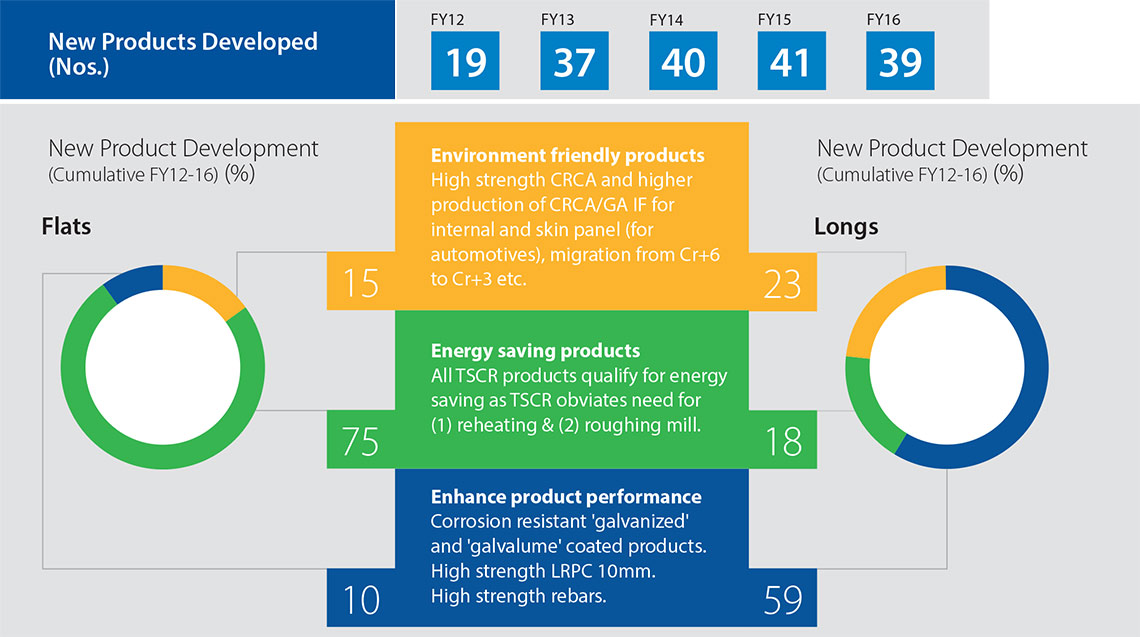

a. New Product Development (39

products developed in FY16).

b. Process improvements that enable

us to improve resource and energy

efficiencies and productivity while

reducing the environmental impact and

operating costs.

c. Superior marketing enabling price

premium over competition and

most-preferred supplier for partnering

by B2B customers.

We develop intellectual capital through strong process flows, collaboration with technology leaders and active encouragement by leadership for learning and experimentation.

Objectives Driving Intellectual Assets Creation

COST COMPETITIVENESS

The objectives of our research and technology initiatives are to support plant operations across the production value chain and make our manufacturing processes robust and efficient.

We have a long value chain – beginning at mining and running through raw material preparation, iron making, steel making, casting, rolling, finishing and finally delivering to the customer. While this makes it a complex business chain, it also offers opportunities for improvement along the length of the value chain. Our main focus areas are higher efficiency in iron ore and coal beneficiation, lower carbon consumption in iron making, optimised steel making mix, efficiency in lowering slag and CO2 generation and improving steel quality to achieve superior steel properties. The technological initiatives driving cost efficiency across the value chain are:

1. Mining

Our main focus is to operate the captive mines more efficiently and responsibly through the use of latest technologies that suit our mining conditions

To enhance the captive coal availability, initiatives such as high wall mining, shaft deepening, faster excavation methodology, use of high capacity equipment, GPS implementation and mechanisation, wherever possible, are being implemented. Likewise, we work towards increasing the clean coal yield through increase in combustible recovery and improvement in separation efficiency. In order to increase productivity of our open cast mines, we are implementing fleet management system (for efficient tracking and control of vehicles), advanced blasting techniques, etc. Further, to improve resource efficiency, we are taking initiatives in the area of beneficiation of ores, reducing iron ore discard to below 45%.

From a safety and cost perspective, we are exploring the applicability of technological developments like autonomous haulage, remote operations centre, predictive maintenance and drones for mine planning for our mining operations.

2. Iron and Steel Making

The major thrust areas in iron and steel making are detailed below:

i. Increase in usable agglomerates in iron making through reducing the sinter return fines to global benchmark level and increasing pellet productivity by 30 - 35%.

ii. Increase in coke strength after reaction through enriching blend with resin addition/shear crushing.

iii. Increase in Blast Furnace (BF) Pulverised Coal Injection (PCI) level (all furnaces) through hardware upgradation, BF control process refinements, increase in flux content and burden quality distribution.

iv. Increase in BF productivity for large BFs through increase in dry coke %, more pellets, increase in Pulverised Coal Injection and reduction in slag.

v. Reduce LD slag generation by 40-50% through designing and installing De-Si process in Blast Furnace cast houses, implementing double slag practice and other similar initiatives.

3. Rolling & Finishing

We have taken up several technology initiatives to improve our product quality – such as RH Degasser, automatic scarfing, vertical bending caster and automotive galvanizing line, among others.

New products such as micro-alloyed high strength steels for automotive, high strength Interstitial Free (IF) steel and Galva Annealed for two-wheeler fuel tanks have been launched. We also achieved cluster of Hot Rolled high-strength steel and became the first domestic integrated skin panel supplier and the first branded cold rolled steel seller.

Our focus in this area is to improve steel cleanliness, achieve benchmark casting speeds, produce wider width rolling steel, eliminate shape issues in cold rolled close annealed coils, eliminate patch defects and standardise snout systems.

CUSTOMER CENTRICITY

For B2B customers, we have developed the required ‘know-how’ to be a partner of choice. This has been achieved through deploying product application resource at customer facilities for real time understanding of issues. Further, cross-functional teams from operations (like product technology, product application and marketing & sales) work together with customers to improve product efficiencies and reduce costs; ensuring transparency and building a win-win culture with customer organisation.

For B2C customers, approaches that have helped us to a premium position with high market share is given in the table overleaf.

The know-how behind high premiums for branded products has been developed through:

- Understanding consumer needs.

- Designing the brand promise around the consumer needs.

- Developing the Ecosystem to deliver Branded offerings.

- Dedicated and high capability channel network.

- Ability to develop Services & Solutions addressing consumer needs.

During the year, we developed the following products

Specialty Hot Roll

- ASTM Grade 50: Type 2 developed for Pre-engineered Building segment.

- X56: HSLA 500 grade developed for Long member.

Specialty Rebar/Application

- Fe 500S Rebar (10-16 mm).

- Seismic Rebar – High ductility

- Fe 600 Grade 36.

- 40 mm High strength for slender structures.

Coated

- JAC440WN for automotive companies.

Wire Rods: HC72A 5.5

- ASTM Grade 50: Type 2 developed for Pre-engineered Building segment.

- X56: HSLA 500 grade developed for Long member.

Specialty Rebar/Application

- Fe 500S Rebar (10-16 mm).

- Seismic Rebar – High ductility

- Fe 600 Grade 36.

- 40 mm High strength for slender structures.

Coated

- JAC440WN for automotive companies.

To meet our customer requirements, we are pursuing new products to be developed under the following categories:

- Platform products for narrowing the technological gap with advanced mills: automotive, lifting & excavation, oil & gas, infrastructure and capital goods among others. For this, we are working on improvements in strength and reduction in the number of surface defects for wheels, internal, structural and fully finished parts, and reduction in hole expansion ratio for structural and wheel parts of automotive.

- Differentiated products: We are developing ultra hi-strength steels, high corrosion steel, super-hydrophobic steel and cost-effective ultra hi-strength steels. Additionally, we will increase our capabilities in downstream value added products by entering into new segments, such as defence, lifting & excavation.

ENVIRONMENT-FRIENDLY PROCESSES

We are committed to minimising the environmental impact of our operations and products through the adoption of sustainable practices and continuous improvement in environmental performance. We have developed several new technological projects linked to waste utilisation and energy conservation such as de-phosphorisation of LD slag, water consumption optimisation through treatment, recycling, process modification to reduce water wastage, energy efficient waste heat recovery, improving combustion efficiency and hot charging.

We are working towards implementing a number of projects, some of which are:

- Reduction in CO2 emission by about 20% through various enablers, like the Top gas pressure Recovery Turbines (TRTs) in blast furnaces, Coke Dry Quenching in coke plants, increased use of pellets, reduction in carbon rate, refining of Basic Oxygen Furnaces (BOF) and hot metal treatment shop.

- Reduction in specific water consumption by 35% through effluent treatment plants, dry Galvanized & Coated Steel Products, dry slag granulation etc.

- Our new plant at Kalinganagar will deploy larger scale units such as 496 m2 Sinter Plant (Jamshedpur 204 m2), 310 tonnes heat size (155 tonnes at Jamshedpur), 6 MnTPA Hot Strip Mill (2 MnTPA stretched to 4 MnTPA at Jamshedpur). This by itself will help reduce heat losses and the adverse environmental impact.

- Towards achieving zero discharge of effluents, we are developing a new approach of tertiary treatment of water discharged from the coke oven.

- In order to reduce landfills, we are reusing BOF slag as cement substitute, road construction and railways ballasts, paver blocks and recovering valuables through smelting.

- Use of environment-friendly, Restriction of Hazardous Substances (RoHS) compliant passivation movement from Cr+ 6 to Cr+ 3.

- An environmental research group has been formed in the R&D Division to carry out Life Cycle Assessment studies for the environmental sustainability of our products. A researcher is associated with World Steel Association as a fellow for expanding domain knowledge and networking within the steel industry.

The Company will continue to work on its strategy of ‘Value from Waste’. We launched Ground Granulated Blast Furnace Slag (GGBS) and a downstream product of Blast Furnace Slag. We re-cycle GGBS into cement to make an even stronger concrete and use it as a partial replacement of Ordinary Portland Cement (OPC) for up to 70%, thus bringing down the cost of concrete. The concrete made by using GGBS is stronger, more durable and eco-friendly. The other benefits of using GGBS are higher ultimate strength, low permeability, resistance to chloride and sulphite attacks etc.

In order to use the waste material and enhance value from it, we are exploring many futuristic ideas ranging from 3D printing to glazing of ceramics made from such waste.

PRODUCTIVITY

During the year, we incorporated appropriate technology to increase productivity. We leveraged information and communication technology for efficient day-to-day operations, automated a few key business processes, developed hole detection system for cold rolled products and implemented IT systems to enhance business and workflow systems for employees, customers, suppliers and partners.

We have several forums (both internal and external) to capture futuristic themes leading to creation of value and intellectual assets. Our initiative ‘Innovent’ focuses on identifying customer requirements by using specific tools and developing them into business concepts.

Focus Areas

In order to support our business and customer focused stakeholders, we aspire to:

1. Assist in developing new, improved products and reduce development cycle time.

2. Enable development of Optical Quality Analysis System (OQAS), an IT-based platform to analyse and process data in IF skin

panel production chain, aided by appropriate knowledge management.

3. Assist in implementing technologies and processes that enable Zero Water Discharge in the life cycle of steel products.

4. Innovate and find cost effective alternatives to stainless steel through coating solution.

5. Enable the utilisation of low-grade manganese ore to profitably produce Ferro alloys through appropriate methodologies.

6. Develop methods to convert non-coking coal to coking coal.

7. Graphene-based coating solutions.

8. Initiate a project on coal beneficiation technology to get 8-12% ash from raw coal of higher ash, for operational savings and

better utilisation of coal.

9. Develop Environmental Product Declaration for our products and use Life Cycle Analysis for eco-labelling.