NATURAL CAPITAL

Natural capital represents all renewable and non-renewable environmental resources such as water, land, minerals, forests, biodiversity and health of the ecosystem.

Approach

We have always been committed to conservation of natural resources, preservation of biodiversity and abatement of climate change impacts due to our operations. There is visible commitment to environmental care and climate change as stated in our Environment, Climate Change, Energy and Sustainability policies.

Recently, we have concluded an assessment of the Biodiversity at our select raw material locations and have plans in place to enhance the same.

We have an Environment Management Department (EMD), a dedicated corporate function, for management of environmental performance of the Company. While we meet regulatory compliances, we are also conscious of the growing emphasis laid by industry associations like World Business Council for Sustainable Development (WBCSD), multi-stakeholder consortia like Natural Capital Coalition and NGOs towards protection of Natural Capital.

Our initiatives and achievements during FY16 towards protecting Natural Capital were:

EMISSION ABATEMENT

The CO2 emission intensity at the Jamshedpur Steel Works has reduced by over 27% in 11 years and by 10% in the last five years. We achieved our best ever monthly performance @ 2.19 tCO2/tcs in February 2016, surpassing the previous best of 2.27 tCO2/tcs in March 2015.

A significant contributor to a lower CO2 intensity in FY16 was a lower coke rate at the blast furnaces. During the year, under the TQM initiative, Shikhar - 25 energy efficiency measures secured abatement of CO2 emissions (approximately 6% reduction of emissions intensity). We also conducted trials at the 3 MW Solar Photo-Voltaic Power Plant at Noamundi (showcased on the adjacent page).

WASTE HEAT RECOVERY

Waste Heat Recovery from the Sulphur Recovery Unit (SRU), yielded cumulated emission abatement of 19,534 tCO2 since it began operations in the last quarter of FY14 till FY16.

We have implemented Waste Heat Recovery System (WHES) in our BF Stoves and used Top gas pressure Recovery Turbines (TRT) at the G, H & I Blast Furnaces which deliver 80% of the Hot Metal. Coke Dry Quenching has been installed at Coke Oven Battery Nos. 5, 6 & 7. These systems have helped us significantly reduce the energy consumption.

ZERO EFFLUENT DISCHARGE

With the enhancement of recovery systems, we achieved our lowest ever specific effluent discharge, amounting to a 36% reduction of discharge in the last five years and 27% reduction in water intensity over the same period. 27 of our 46 operating sites are Zero Effluent Discharge sites.

SOLID WASTE UTILISATION

We focus on extracting value from waste through our practice of reduce, reuse and recycle. Further, we are also pursuing innovative applications with special focus on LD Slag utilisation in agriculture, construction and other sectors.

Our objective of zero waste mining is driven through processes such as ore characterisation, ore-body modelling and block modelling of mining deposits done, LCI studies for mines, etc. State-of-the-art beneficiation plants are in operation and studies are underway for beneficiating slime and low-grade ores.

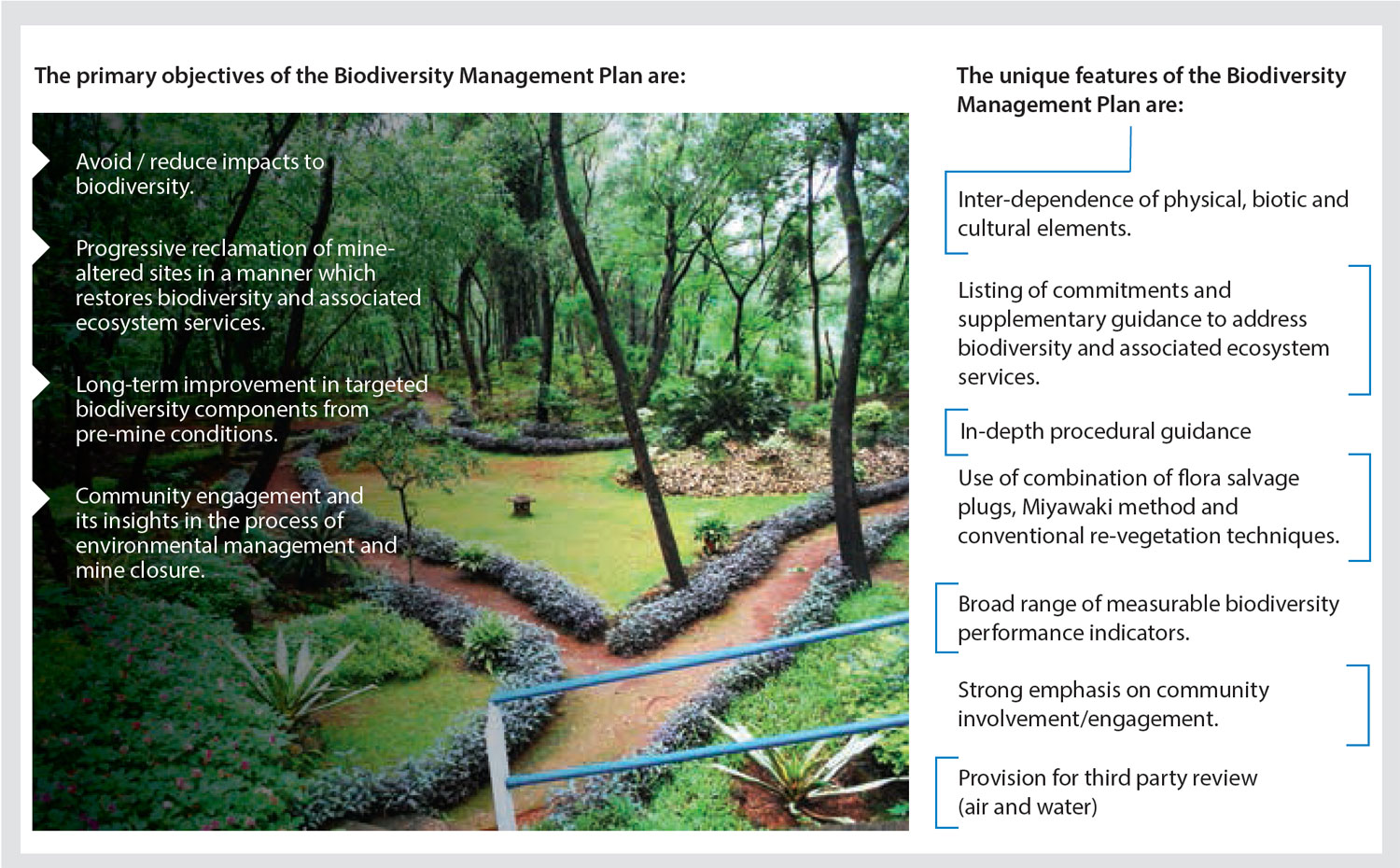

BIODIVERSITY MANAGEMENT

Biodiversity Management Plan for raw material locations is a collaborative effort between Tata Steel and the International Union for Conservation of Nature (IUCN). The Management Plan is intended to provide practical guidance for the progressive restoration and enhancement of biodiversity within the mines and to the extent possible, within the adjacent impacted areas. The measures proposed in the plan will be subject to annual reviews which will strive for a system of continuous, adaptive improvement.

The guidance provided in the plan has been derived from our commitment to restoration of biodiversity, the experience derived from the recent mine closure proceedings, biodiversity assessment, companion preliminary community consultation process and the guidance received from IUCN, International Council on Mining and Metals, Indian Bureau of Mines, World Bank/International Finance Corporation guidance on mine reclamation and closure.

Usage of various wastes generated

| MATERIAL | USAGE |

| Jamshedpur Steel Works | |

| Solid Waste (Majority is BF slag & LD slag) |

Recycled: Sold to Cement makers and recycled in steel making |

| Mining | |

| Overburden Dump (toe-wall, garland drain) |

Reused: Partially used for backfilling of demineralised pits used for reclamation and rehabilitation, also exploring usage of carbonaceous shale |

| Tailings | Reduced: Management of Tailing Pond Reused: Onsite storage, de-watering, agglomeration Recycled: Tailing from Washeries are sold to third parties |

| Reject Coal | Reused: Used in captive power plants Recycled: Sold outside |

| Other Locations | |

| Slag | Recycled: Half of the slag quantity is sent out for SiMn production by EPA Reused: Balance is landfilled |

Raw material locations have taken up projects as part of the Annual Business Plan, for implementation of biodiversity management plans such as the:

- Butterfly Park at Sukinda and Joda.

- Niche Nesting (Artificial bird nesting boxes) at Noamundi.

- Developing local forest in dump area at Sukinda.

- Integrating rain water harvesting structures in periphery for improving aquatic life at Sukinda.

- Agro-biodiversity enhancement at Jharia.

- Dump reclamation using Mulberry Plantation at West Bokaro.

Some of the other stakeholder engagement initiatives are 'Spot the Species', 'Green Therapy', 'Jaiba Kala Vividhata', 'Prajatiya Khadyotsav' and 'Snakes are Friends'.

Biodiversity assessment done with IUCN has revealed that in some of the mining sites, biodiversity in our lease area is better than outside our lease area and that is a testimony of our efforts towards maintaining greenery and water harvesting. Environment management plans and progressive mine closure plans are also in place and are being monitored and reviewed internally by Indian Bureau of Mines.

Key Technological Developments and Innovations

Some of the key technological developments and innovations for improvement of natural capital while caring for the safety and productivity of human capital are as follows:

- Surveillance of service vehicles through GPS-based tracking system and speed monitoring device was implemented at Joda East Iron Mine.

- Steps taken towards green energy - Installation and trial of 3 MW Solar Power Plant completed at Hill #1 of Noamundi.

- 13.7% reduction in energy consumption in Ores, Mines and Quarries township areas achieved through various initiatives like replacement of conventional light fittings with LED lights, installation of energy-efficient fans/air conditioners, monitoring and communication (through SMS) of energy consumption of individual houses etc.

- Introduction of pre-fabricated vertical drains for embankment construction of Slime Dam at Noamundi. The vertical drains will enhance the stability of the dam after the augmentation of the slime storage capacity.

- Advanced blast monitoring and vibration management projects were successfully conducted for excavation of critical top benches of Banspani hill at Joda East Iron Mine and Khondbond Iron Mine.

- Aquifer-based Water Harvesting technology used for the Bokaro River project to supply 1,000 KL of water per day to seven surrounding villages with 7-8 km piping laid out.

- Installation of the Man-Riding system for transportation of man and light load in underground mines. It has been commissioned in Sijua Colliery and has reduced the average travel time by 70%, eliminated exhaustive travelling and has resulted in productivity improvement of employees. Similar systems may be installed in two other collieries of the Jharia Division.

- An air-cooling system to be installed in the Digwadih Colliery to enable reduction in the temperature of underground mines, and thereby help increase the productivity of mines.

Our compliance to most stakeholder expectations has yielded significant benefits such as early issuance of permits for Mines, Steel Works at Jamshedpur and Kalinganagar. As a result of our dedicated efforts, we have significantly improved in the areas of energy consumption, CO2 intensity and Stack (dust) emissions.

Water Performance (Tata Steel India)

| WATER AND EFFLUENT MANAGEMENT | UoM | FY14 | FY15 | FY16 |

| Water Withdrawal | mn m3 | 76.99 | 74.38 | 63.06 |

| Effluent Recycled and Reused | % | 17.8 | 22.2 | 29.4 |

| Effluent Recycled and Reused | mn m3 | 16.70 | 21.28 | 26.30 |

Emission Performance (Jamshedpur Steel Works)

| EMISSION TRENDS AND ENERGY INTENSITY | UoM | FY14 |

FY15 |

FY16 |

| Specific Particulate Matter Emissions (stack) | kg/tcs | 0.88 |

0.57 |

0.5 |

| Specific Effluent Discharge | m3/tcs | 2.31 |

2.31 |

1.2 |

| Specific Make-up Water Intake | m3/tcs | 5.57 |

5.54 |

4.39 |

| Solid Waste Utilisation | % | 78.0 |

78.30 |

80.6 |

| CO2 EMISSION INTENSITY | UoM | FY14 |

FY15 |

FY16 |

| Direct Emissions (scope-1) | tCO2/tcs | 2.23 |

2.26 |

2.11 |

| Emission (Direct + Indirect) | tCO2/tcs | 2.43 |

2.42 |

2.26 |

| Energy Intensity1 | GJ/tcs | 25.19 |

25.17 |

24.15 |

Focus Areas

Our aspiration is to be the 'Indian Steel industry benchmark in Environment Performance' and to achieve this we are focused on:

- Implementing Zero Effluent Discharge solutions.

- Reducing GHG emissions through coke rate reduction.

- Implementing solutions/ initiatives to improve Solid Waste Utilisation.

- Abating dust emissions through installation/augmentation of fugitive dust extraction/ suppression systems.

- Managing biodiversity, an emerging focus area and of significant relevance to us due to our mining operations.