Report Menu

Report Menu

Intellectual capital

Innovating tomorrow with technology and digitalisation

Tata Steel aspires to be a pioneer in leading the fourth industrial revolution and is committed to developing cutting-edge technologies, and design solutions, that help transform processes, leverage digital technology to improve efficiencies, and enhance customer experience.

* New product is defined as product developed at Tata Steel through new processes and technology and then commercialised

launched`114

Amidst changing customer needs, competition from alternate materials and increasing regulatory risks, we strive to continuously innovate and adapt to change.

STRATEGIC FOCUS

- SO3

Technology and a culture of continuous improvement are key enablers towards achieving the strategic objectives of industry leadership and cost leadership.

WAY FORWARD

- We will continue to enhance our new product portfolio, cost competitiveness, and environmental performance through capability building and collaboration with technology and research partners.

- We aim to co-develop and adapt new business models that can bring about a paradigm shift through world-class partners and start-ups.

GOALS

To be one of the top five technologically advanced global steel companies

IMPACT ON SDGs

Innovation focus of Tata Steel

We are focussed on leveraging our R&D capabilities through

New products

Advanced materials

Process improvements

Digitalisation across the

value chain

Innovation is driven and leveraged by the technology organisation, new materials business, and services and solutions business. The process also focusses on building new competencies and capabilities to enable our organisation to be future-ready.

SO3 - Insulate revenues from steel cyclicality

Driving innovation at Tata Steel

Tata Steel has a two-pronged approach towards innovation, supported by robust resource allocation and organisational commitment.

We engage engages in innovative ideas that lead to significant continuous improvements driven by the transforming the business landscape, enabling us to become best-in-class, and setting benchmarks in the industry.

We also pursue breakthrough ideas to create new value propositions, businesses and technology shifts.

Factors that help us drive innovation

Our R&D function has over 200 researchers and collaborations with 40 institutes.

In-house platforms such as Innovent support our strong culture of innovation. Innovent focusses on identifying key customer insights and translates them into tested and scalable business models.

Innovation council led by R&D aims to generate novel ideas and enable implementation. New collaborations as well as advancements in new materials and solutions are some key outcomes of this process.

We have set up enhanced research facilities with latest laboratories such as APERTA (Thermochemical Simulation), enGENE (Biotechnology Solutions), PEARL (Product Forming and Performance Research), SeFondre (Welding) and Reynolds (Mathematical Modelling).

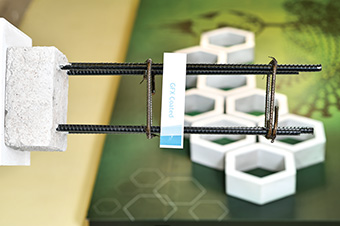

India’s First Fibre Reinforced Polymer (FRP) based Foot Over Bridge Installed at R&D Division, Tata Steel Jamshedpur

New product development

Special focus was given to new steel product development for the Pre-Engineered Building (PEB), Lifting and Excavation (L&E) and Oil & Gas (O&G) segments. The production facility at Kalinganagar helped develop new products in an accelerated timeline. In-house R&D efforts, collaboration with Tata Steel Europe and technical institutions helped us expedite the product and process design for these products.

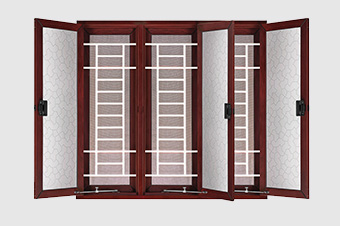

Tata Steel has developed and successfully commercialised the first-of-its-kind Pravesh Vista steel windows in Financial Year 2018-19. This product has won the 8th CII Design Excellence Awards 2018 under the Industrial Design: Architecture and Interior Products category

New materials

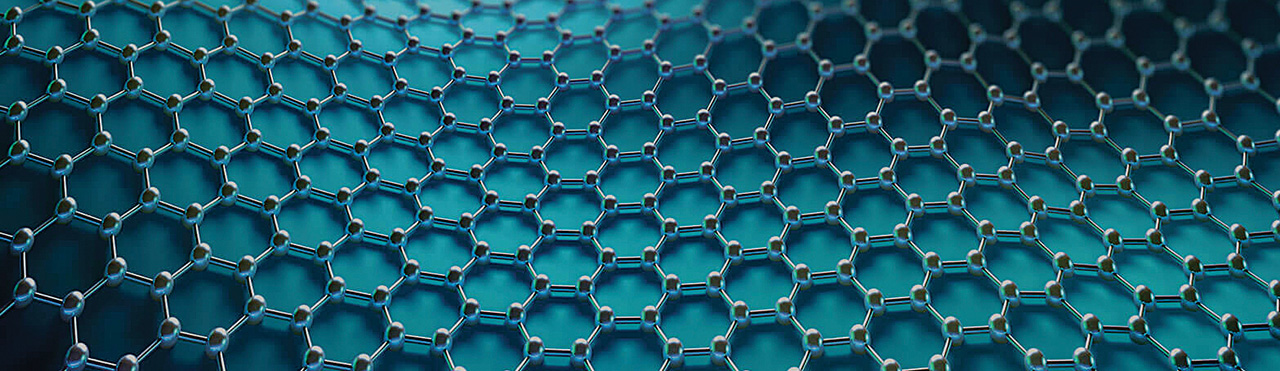

Graphene

Graphene-doped plastic products that were used in Tata Steel for industrial use showed a two-fold increase in life as compared to existing products.

Fibre Reinforced Polymer (FRP)

Our new materials business has adopted an asset-light model through partnerships and collaborations to develop FRP products that cater to automotive, industrial, infrastructure, and railway sectors. This includes FRP solutions for streetlight poles, pressure vessels, pipes, modular toilets, chemical tanks, and foot over bridges.

To enhance our innovation in this segment, we are collaborating with National Composite Centre - Bristol UK, Indian Institute of Science - Bangalore, IIT Roorkee, NIT Rourkela and other Council for Scientific and Industrial Research (CSIR) Labs. Apart from FRP Composite and Graphene, there is focus on building other advanced materials, e.g., ceramics, into our portfolio to expand the New Materials Business.

Process improvement

Use of High Gradient Magnetic Separator (HGMS) for iron ore slime beneficiation

Currently, the Noamundi iron ore mine discards 16% of wet run of mine output as slime, which has 8% alumina and 55% iron content. Implementation of HGMS is expected to recover 50% of slime containing iron content of 63%. This initiative is in its pilot stage and is expected to save virgin raw materials and increase mine life through improved beneficiation.

Reducing carbon footprint using Carbon Composite Briquettes

Sintering route has low carbon utilisation as super fines escape through the sinter bed, resulting in low efficiency and poor work environment. A new technique of super fine agglomeration called carbon composite briquetting was developed and charged into the blast furnace. A successful plant trial resulted in a favourable drop in coke and carbon rate. This will be adopted across facilities over the next three years.

Moving ahead with digitalisation

In Financial Year 2018-19, we embarked on a long-term digital technology led business transformation programme to drive value creation across the enterprise. We have set ourselves stringent targets towards digitalising our plants and processes, and have taken definitive steps towards building capabilities to deliver transformative solutions. The goal is to become agile, intelligent and smart in all our business processes, and enhance stakeholder experience, while generating substantial EBITDA improvement.

Domains under focus for digitalisation

Our key business transformation initiatives are in the domains of Integrated Supply Chain and Logistics, Smart Asset Maintenance, Customer-facing Digital Platforms, Smart Closure of Financial Accounts, Smart Procurement, and Energy Management.

To drive and sustain transformation of this scale and deploy digital solutions, we have structurally altered our IT infrastructure spend. We have moved from being capex-heavy to capex-light by opting for managed services to augment the IT layers of connectivity, infrastructure and cyber-security.

DATA SECURITY

With increasing connectivity and data flow, we are exposed to the risk of new-age cyber crimes. We have deployed a full-scale Security Operations Centre (SOC) to safeguard our IT and Operational Technology (OT) data and applications, which has the capability to analyse 30,000 events/sec, resulting in proactive detection and defence from cyber threats.

PREDICTIVE ANALYTICS

We have built and deployed over 40 Advanced Analytics models to enhance operational efficiencies, which include:

- Reduction of ore stickiness in our iron ore mines and turnaround time of wagons, leading to lower demurrage

- Reduction of downtime of apron feeders

- Improvement in quality of pellet, coke and sinter to blast furnaces at optimum cost and lower emission, further aided by in-process hot metal temperature and furnace

- Permeability prediction models that improve iron making at reduced coke rates

- Optimisation of the slitting of mother coils to reduce yield loss at Steel Processing Centers, and reduction of Stock Keeping Units of Pravesh doors that resulted in improved delivery time for customers

- Optimisation of our distribution costs

CUSTOMER INTERFACE

Our customer-facing digital platforms–Aashiyana, DigECA and Compass–have resulted in additional revenue and continue to be one of the enablers in improving our customer satisfaction.

Tata Steel joins the CII led collegium of futuristic business houses to pledge support to the start-up ecosystem

‘Mind Over Matter’ Programme - Tata Steel’s Annual Innovation Challenge for Engineering Students

INDUSTRY KNOWLEDGE LEADERSHIP AND COLLABORATIONS

Tata Steel leads industry efforts in supporting knowledge transfer and capability building across and beyond its sector. We have worked extensively with the Government and regulators to shape policies that influence the sustained economic growth towards national priorities. Our leadership is on numerous committees that engage in dialogue on issues ranging from environment, financial practices to social initiatives and others. Our senior leadership is engaged at a global level to help formulate paths towards Industry 4.0.

Our organisation regularly supports industry bodies and peer networks in sharing best practices, training, research, and ideas that enhance the overall performance of the Indian industry. Events such as annual fraternity meets are held for maintenance communities that connect engineers from all locations with the objective of sharing best practices and achievements.

Other forums used to promote cross-learning and sharing of best practices are the shared services technical meet and quarterly meet of experts at Kalinganagar.

Tata Steel collaborates with various technical institutes and technology start-ups/SMEs nationally and internationally to create an ecosystem for cross-learning and collaborative working. The collaborative projects range from emerging technologies, environment, Artificial Intelligence, robotics and other long-term research assignments. These collaborations work in a two-way manner where students from institutes work at Tata Steel and Tata Steel employees are sent for research fellowships to study at different universities. Tata Steel is also engaged with government funded research programmes such as Uchhatar Avishkar Yojana (UAY). The Value Analysis and Value Engineering (VAVE) programme is an engagement mechanism where Tata Steel engages with customers on topics such as how best to use steel, simulations, modelling for light weighting, and optimum material usage.

The senior leadership of Tata Steel is part of various national level research missions such as the Centre of Excellence in Steel Technology (CoEST, IIT Bombay) and the Advanced Manufacturing Centre at IIT Kharagpur, among others.

CONTINUOUS IMPROVEMENT - SHIKHAR25

Total Quality Management (TQM) is deeply embedded in the ethos of Tata Steel. It involves all sections of the workforce in driving improvement projects for enhancing performance. Initiatives for achieving operational excellence have reduced operational cost and environmental impact while delivering higher EBITDA margins.

The Shikhar25 programme focusses on delivering superior product quality, optimising product mix, improving operational efficiency to lower carbon footprint, reducing waste generation, improving waste utilisation, and maximising energy and material efficiency.

In Financial Year 2018-19, we successfully implemented 427 Shikhar25 projects, resulting in total savings of ₹2,801 crore. We also increased the coverage of Shikhar25 and started two new IMPACT centres. These IMPACT centres focus on cross-functional themes, digital initiatives, new technology, and collaboration with suppliers to identify new avenues for improvement.

In addition, we implemented over 34,000 kaizens, 367 green belt projects and over 100 other TQM projects. We achieved 92.6% employee involvement in improvement activities. ‘Manthan Ab Shopfloor Se (MASS)’ is an idea generation initiative for shop-floor employees, focussing on issues such as safety, cost, operational excellence, environment, etc.